EPD A1 to A3 vs A1 to A5

Trying to decide whether your next EPD should report A1 to A3 or A1 to A5? The answer shapes how buyers assess your product’s upfront carbon and how smoothly you pass procurement checks. Here is the fast, practical breakdown manufacturers ask for when comparing “EPD A1 A3 vs EPD A1 A5.”

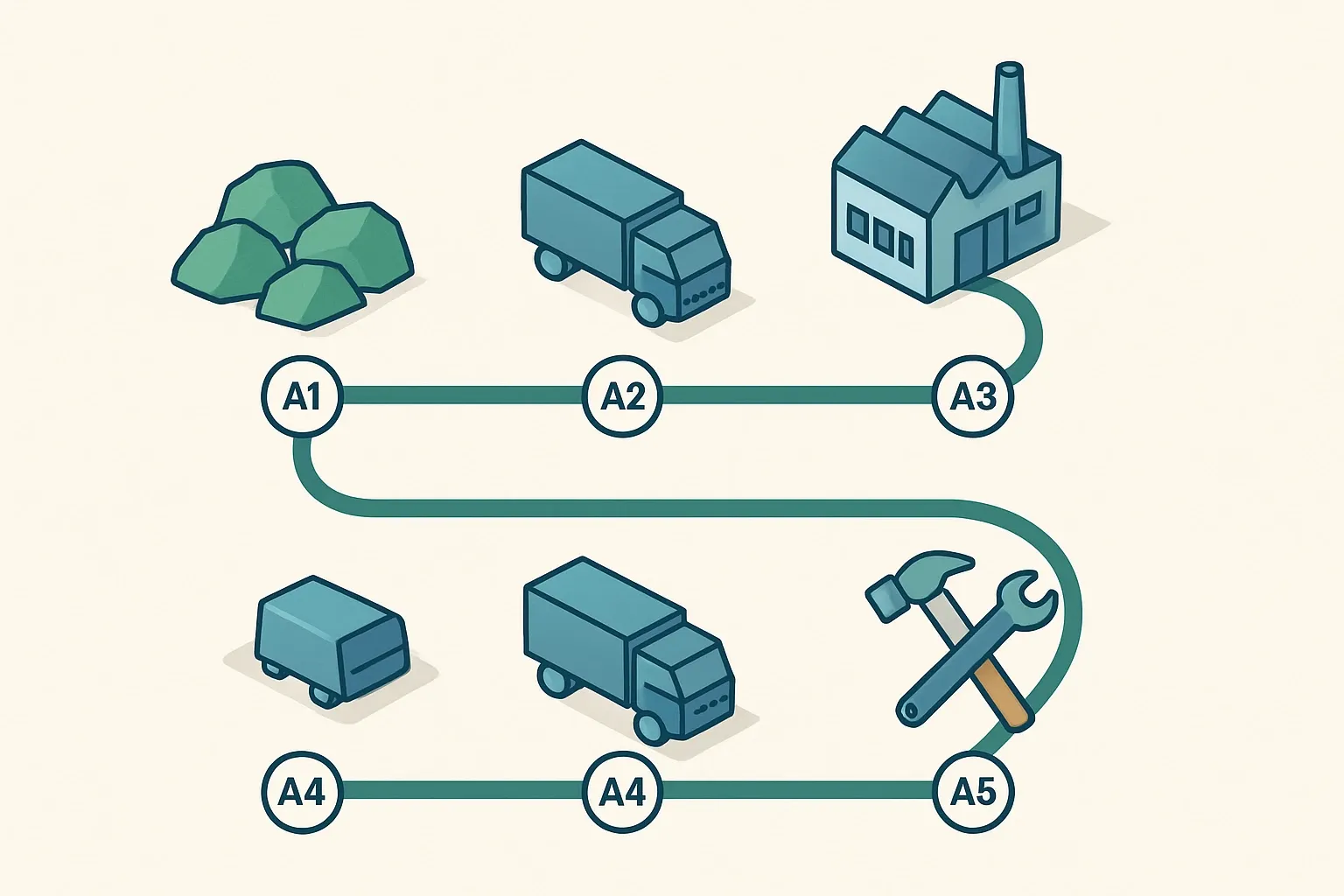

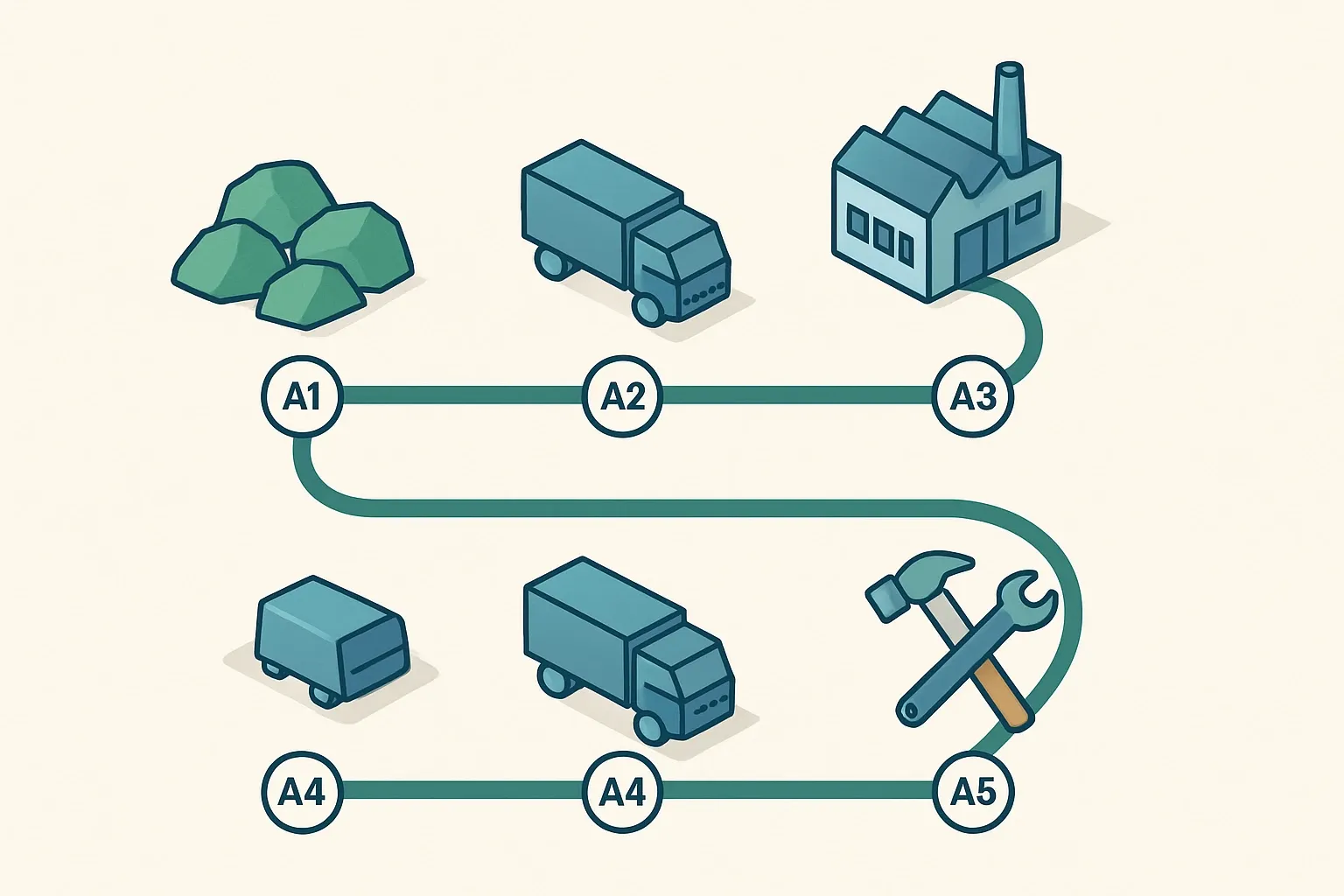

The life‑cycle map, simplified

A1 to A3 covers your factory gate story. Think raw material supply, inbound transport to your plant, and manufacturing. A1 to A5 adds delivery to site and installation. Many EPDs stop at A1 to A3. Many whole‑life methods count upfront carbon as A1 to A5, so site logistics and installation enter the frame.

Why buyers care about the scope label

Procurement teams want apples to apples comparisons. If a spec asks for upfront carbon, they often mean A1 to A5 because that is how whole‑life frameworks define it. RICS’ Whole Life Carbon Assessment second edition took full effect on 1 July 2024 and defines upfront carbon as the production and construction stages combined, that is A1 to A5 (RICS WLCA, 2024).

What exactly sits inside each module

- A1: raw material extraction and processing.

- A2: transport of those materials to your facility.

- A3: core manufacturing, on‑site energy, direct process emissions, in‑plant waste.

- A4: delivery from your gate to the project site, including mode shares and distances.

- A5: installation at site, typical wastage, auxiliary materials, on‑site energy for fixing or curing, and packaging disposal.

The commercial trade‑off in one picture

A1 to A3 is quicker to model and usually enough for basic EPD credit requirements. A1 to A5 tells your real delivered‑and‑installed story which can win tie‑breaks on projects that budget upfront carbon at early design. If your product is heavy, travels far, or requires on‑site curing or adhesives, A4 and A5 can move the needle.

How much can A4 matter

There is no universal percentage because mode, route, and load factor dominate results. Rail can cut per ton‑kilometer impacts compared to road, and full truckloads usually beat partial loads. Reliable cross‑category averages are scarce, so do not quote a generic percent. Model your lanes and typical order sizes instead.

Installation impacts that surprise teams

A5 is not just a waste factor. It can include temporary power for lifts or heaters, solvents or water for clean‑down, and packaging treatment. For finishes, small bottles of adhesive can add up at scale. For concrete or mortar products, site energy and mixing water can become noticeable. Document the likely on‑site method, not the idealized one.

Confused about EPD A1 to A3 vs A1 to A5?

Follow us on LinkedIn for insights on how to make informed decisions that enhance your project specifications and win more tenders.

Data you need at hand

- A1 to A3: 12 months of primary plant data for energy, fuels, water, scrap and yield, and supplier mixes for key inputs. Pick a clear reference year.

- A4: typical shipping modes and distances to your main markets, average load factors, backhaul assumptions, and refrigeration if applicable.

- A5: realistic installation scenarios, waste rates by component, auxiliary materials per unit, and packaging end‑of‑life at site. If data is thin, use transparent scenarios and flag assumptions so reviewers can follow the math.

What standards actually require in 2025

EN 15804 requires A1 to A3 as mandatory declared modules. A4 and A5 are conditionally declared and often requested by clients, especially where upfront carbon is a reporting line. EPDs typically remain valid for five years across major program operators, with updates triggered sooner if results shift by about ten percent depending on the operator’s rules (EPD International FAQ, 2024).

Programme operator timelines that affect scope choices

If a construction PCR version is sunsetting, it can change what must be declared and how results are grouped. The International EPD System confirmed the sunset of construction PCR 2019:14 version 1.3.4 on 20 June 2025, which influences current EPD planning and verification windows (EPD International, 2025). Plan scope early so verification is completed under the intended ruleset.

Where LEED v5 fits

LEED v5 is in progress. Draft language and industry guidance continue to emphasize credible product‑specific EPDs and better accounting of upfront carbon. Teams using LEED v5 pilots or owner standards that mirror WLCA practices should expect more questions about A4 and A5.

When A1 to A3 is enough

- Your immediate targets only ask for a product‑specific EPD with cradle‑to‑gate scope.

- You sell mostly within short haul to site with minimal installation materials.

- Speed matters for an upcoming bid and you need a compliant declaration now, not in months.

When A1 to A5 is the smarter play

- Your customers do WLCA budgeting and request upfront carbon values.

- Long logistics routes, specialized packaging, or on‑site curing could make you look worse if left to generic defaults.

- You want to shape the narrative with real lane data and installer methods instead of leaving A4 and A5 to project‑team assumptions.

How to minimize rework

Decide your desired scope before data collection starts. Capture shipping and installation scenarios in the first pass, even if you publish A1 to A3 first. That way, expanding to A1 to A5 becomes an incremental update, not a reinvention. It is definately easier to widen scope when the raw data is already structured.

Validity, updates, and the five‑year clock

Plan on a five‑year renewal for the EPD itself, even as PCRs evolve. The International EPD System notes that EPD validity is normally five years, with interim updates required if any indicator worsens by more than ten percent, and that transitions to newer PCRs are handled at renewal or update moments (EPD International FAQ, 2024).

Bottom line for manufacturers

If buyers talk about upfront carbon, target A1 to A5. If you need speed to get in the game, publish A1 to A3 and build the A4 and A5 dataset in parallel so an update is painless. The winning move is clarity on scope and assumptions, because scope labels are not just letters. They are the rules of the game your product is judged by.

Frequently Asked Questions

Do we need A1 to A5 to be competitive in public tenders?

Check the tender’s definition of upfront carbon. Many frameworks align upfront carbon with A1 to A5, which means A4 and A5 are expected for comparison and budgeting (RICS WLCA, 2024).

Will an EPD become invalid if the PCR changes during its five-year life?

No. Published EPDs retain their stated validity. Updates or renewals adopt the current PCR version, so schedule time for recalculation when you renew (EPD International, 2025).

Is there a standard percent for A4 transport to use when we lack data?

No credible one-size-fits-all value exists. Results vary with distance, mode, vehicle efficiency, load factor, and backhaul. Use transparent modeled scenarios instead of generic percentages.