EPDs in the United Kingdom, explained for manufacturers

Selling into the UK and hearing BREEAM, PAS 2080, or EN 15804 on repeat? Here is the no‑nonsense map. What counts as a UK‑ready Environmental Product Declaration, where it moves the needle with clients, which program operators are common, and how to get from scattered plant data to a verified PDF without derailing your team’s day jobs.

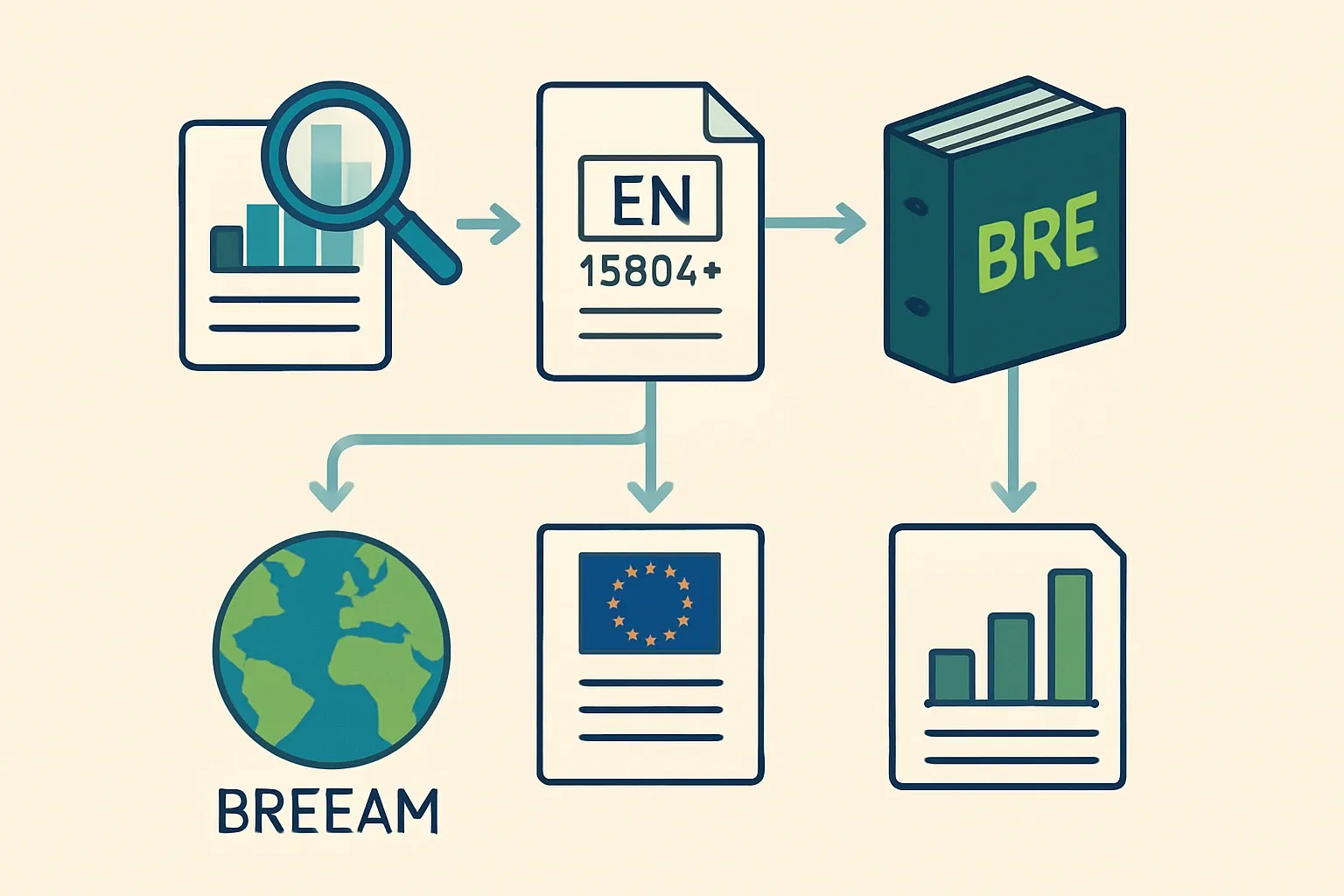

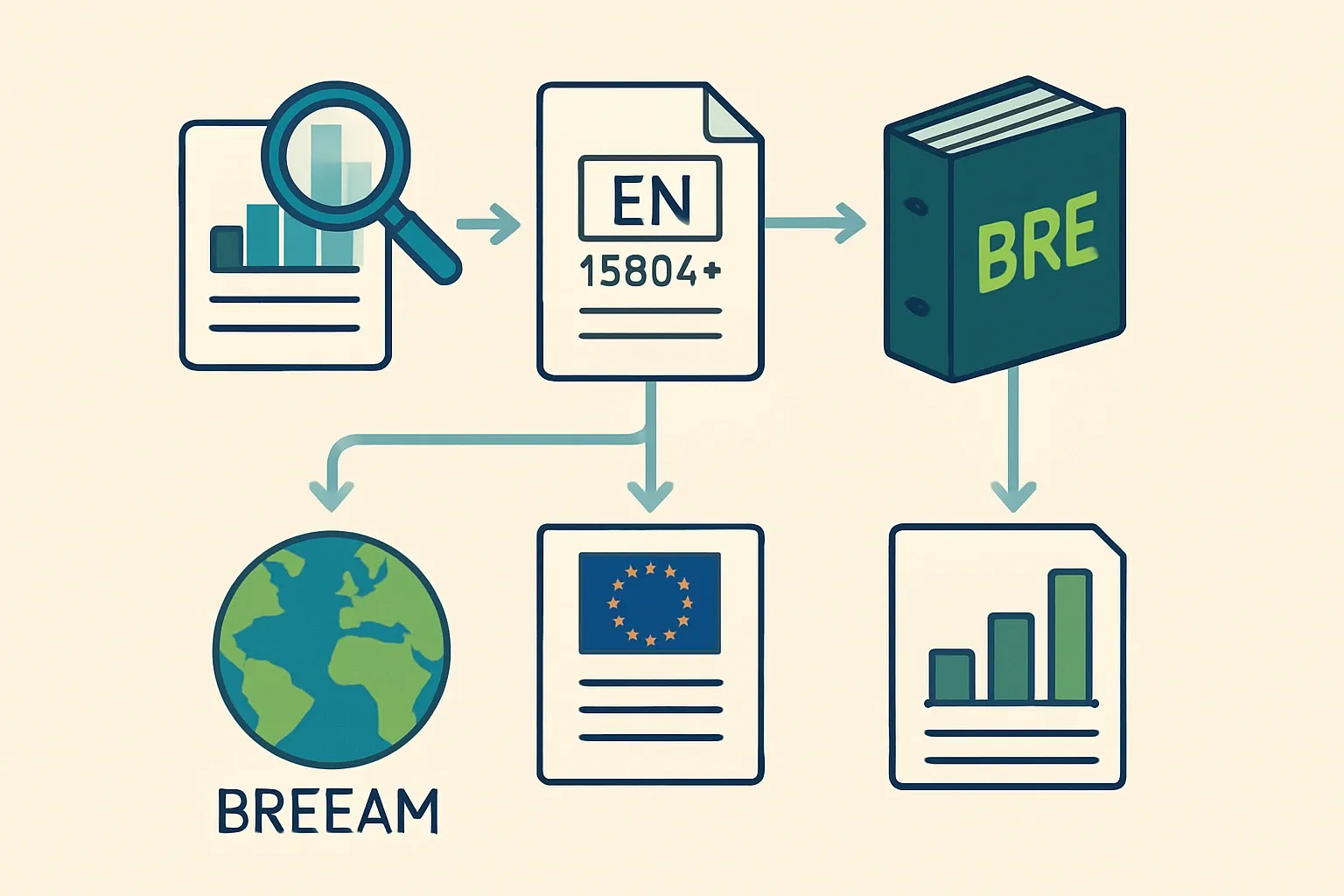

The UK EPD basics in one view

If your product needs an EPD United Kingdom style, start with EN 15804+A2 as the core rulebook, verified under ISO 14025 and a peer‑reviewed PCR. Publication can be with any credible program operator that works in Europe and the UK. The document needs third‑party verification, clear declared unit and system boundary, and the usual A1 to D life‑cycle modules.

Where EPDs move the needle in UK projects

On building jobs, EPDs feed BREEAM. Verified product EPDs contribute in Mat 01 and Mat 02, with credits available when enough products carry product‑specific, third‑party verified EPDs (BRE, 2025). That same verified data also improves whole‑building LCA model quality that design teams rely on during value engineering.

Public clients assess suppliers’ carbon maturity. Central government requires a Carbon Reduction Plan for most procurements above £5 million per year, which affects material suppliers on large frameworks and projects (Cabinet Office, 2025). An EPD is not the CRP itself, but it is often the only credible way to evidence embodied carbon assumptions behind your product claims.

Planning authorities and whole‑life carbon expectations

London’s Whole Life‑Cycle Carbon guidance expects robust product data in WLC assessments and references BS EN 15978. It sets a 60‑year reference study period and encourages use of verified EPDs to support modules A to D submissions (GLA WLC guidance, 2024).

Separately, the RICS Whole Life Carbon Assessment standard second edition came into full effect on 1 July 2024, becoming the default for UK practitioners and clients who want consistent WLC reporting across buildings and infrastructure (RICS, 2024).

Infrastructure and PAS 2080

Infrastructure buyers are raising the bar. National Highways states that contractors and sub‑contractors are expected to implement PAS 2080 carbon management systems by the end of 2025, with verification pathways and evidence requirements published for suppliers (National Highways, 2024). For manufacturers of materials that flow into highways, rail, and utilities, being ready with transparent product carbon data and verifiable reductions is a pre‑qualification advantage.

Want to maximize your EPD potential in the UK?

Follow us on LinkedIn for insights that help you win tenders and unlock new market opportunities.

Program operators you will see on UK EPDs

Manufacturers commonly publish with BRE Global in the UK, and with pan‑European operators such as The International EPD System, IBU, Kiwa and others. Most are members of ECO Platform, which aligns procedures so an EPD issued in one scheme is widely recognised across Europe. Publication location is less important than quality, verification, and EN 15804+A2 alignment.

Picking the right PCR and staying aligned

Think of PCRs as the genre rules of a music competition. Choose the one your competitors use to keep comparisons fair. Check the revision timeline so your verification does not collide with an imminent update. For construction products in Europe the baseline is EN 15804+A2, with product‑specific PCRs where available. When none fit perfectly, a well‑chosen generic construction PCR can be acceptable until a tighter one appears.

Timelines, data and verification in the UK

Most EPDs are valid for five years before renewal, which suits typical product update cycles (BRE, 2025). Expect one reference year of plant data, covering energy, materials, water, waste and transport. Prospective EPDs can work for new lines if you have several months of data, with a commitment to refresh after a full year. Speed depends on how efficiently you collect multisite data and how smoothly the verifier review goes. A partner who handles the heavy lifting across plants, ERPs and utility portals will keep your engineers focused on operations, not spreadsheets. It definately helps.

Where the ROI shows up

- Tender access improves when clients ask for verified product data in WLC submissions and BREEAM materials evidence.

- You avoid punitive generic factors that can make your product look worse on paper than it performs.

- Sales teams stop skipping carbon‑sensitive bids because the lead time for evidence used to be a blocker.

Across many UK bids, having product‑specific EPDs is the difference between being considered on merit or being simplified into a generic factor with a penalty.

Avoid these UK‑specific pitfalls

- Publishing to A1–A3 only when specifiers expect A1–A5 or full A to C for key components.

- Using out‑of‑date datasets that clash with EN 15804+A2 indicators.

- Forgetting BREEAM evidence packs. Include the verified EPD, scope notes, and a short specifier explainer.

- Letting PCR expiries sneak up during verification. Time your review window.

A smarter way to get there

If speed, ease and completeness matter, prioritise a workflow that centralises data collection, tracks PCR and standard changes, and stays operator‑agnostic so you can publish with BRE in the UK or a European program operator as the project demands. We prefer doing the orchestration and verification prep behind the scenes so your R&D and plant leads do not become accidental LCA analysts.

Frequently Asked Questions

Does the UK legally require product‑specific EPDs today?

No national law mandates EPDs across all products. Demand comes from BREEAM credits, planning authority WLC expectations, infrastructure buyers using PAS 2080, and central government procurement rules that require Carbon Reduction Plans for contracts above £5 million per year (Cabinet Office, 2025).

Which standard should a UK EPD follow?

EN 15804+A2 for construction products with ISO 14025 type III rules. Align the EPD with the PCR your competitors use and ensure third‑party verification.

How long is a UK EPD valid?

Typically five years before renewal, per common program operator rules such as BRE’s scheme (BRE, 2025).

How do London WLC submissions affect manufacturers?

GLA WLC guidance expects credible product data and uses a 60‑year reference period, which pushes design teams to prefer products with verified EPDs ready for A to D reporting (GLA WLC guidance, 2024).

Is PAS 2080 relevant to product manufacturers?

Yes. Infrastructure clients increasingly require suppliers to align with PAS 2080. National Highways expects contractors and sub‑contractors to implement PAS 2080 systems by the end of 2025 (National Highways, 2024).