The PCR for Protective Coatings, Explained

Picking the right rulebook for your coating EPD can feel like choosing a streaming plan without reading the fine print. This quick guide maps the real options for protective, architectural, resinous, powder, and roof coatings so teams can lock a compliant path fast, avoid costly rework, and get specified more often. If you’ve ever searched for “pcr for protective coatings,” you’re in the right place.

PCRs in plain English

A Product Category Rule is the rulebook your LCA must follow to create an EPD. Think Monopoly. Same board, same money, but different house rules change the game. Pick the wrong PCR and your results will be rejected by reviewers or program operators.

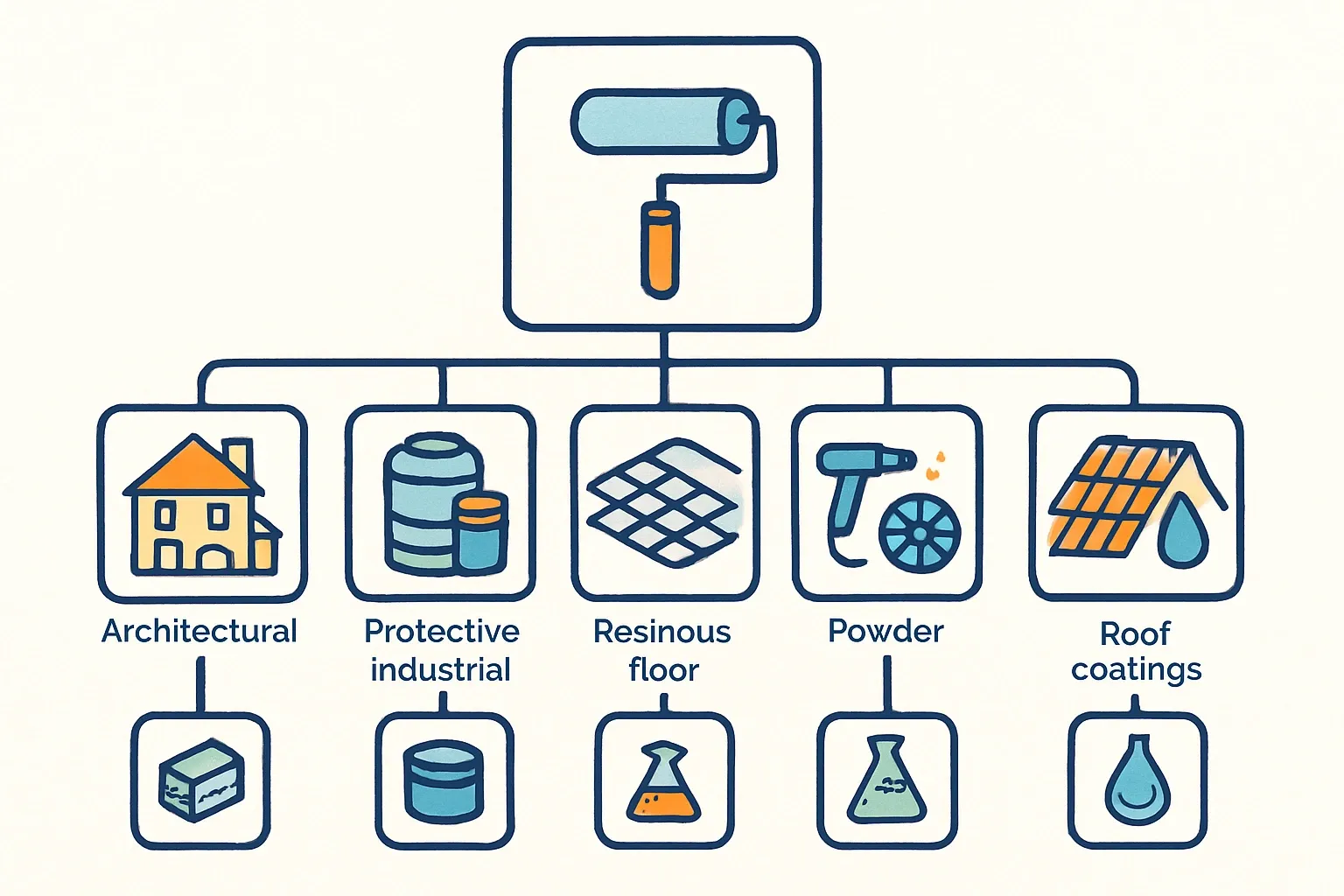

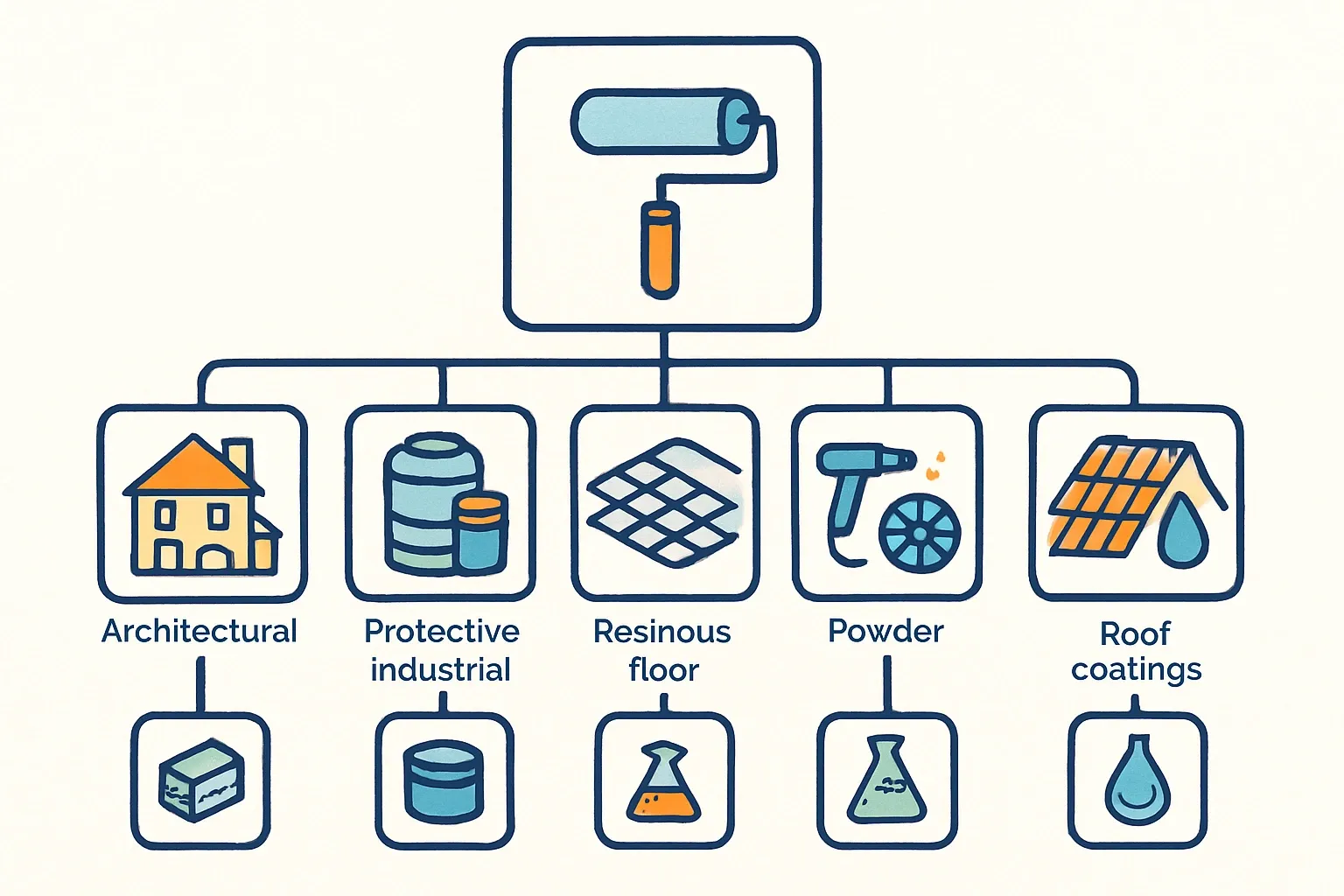

Which PCR typically fits a coating

Protective coatings span several PCR families. The right one depends on chemistry, use phase, and where you will publish.

- Architectural or maintenance paints used on buildings. Often covered by architectural coatings PCRs under ISO 21930 or EN 15804 Part A with a coatings Part B.

- Industrial protective systems for steel or concrete, including zinc primers, epoxies, and polyurethanes. Frequently aligned to EN 15804 with a coatings Part B that sets film build, coverage rate, and system definitions.

- Resinous floor coatings and terrazzo systems. Usually mapped to a dedicated resinous floor coatings PCR.

- Powder coatings. Often covered by a specific powder coatings PCR or a coatings Part B under EN 15804.

- Roof coatings and liquid-applied membranes. Commonly handled by a roof coatings PCR in North America or a coatings Part B in Europe.

If you are unsure, look at competitors’ recently verified EPDs and follow the same PCR family. That keeps specifiers comparing apples to apples.

EN 15804 or ISO 21930

Most construction EPDs in Europe reference EN 15804. North American coating EPDs commonly reference ISO 21930. Both are valid. Program operators care that your LCA follows the correct core rules and the correct coatings Part B when required. Mixing frameworks in one portfolio makes benchmarking awkward for customers.

Indicators buyers actually read

Under EN 15804+A2, EPDs report 13 core environmental indicators, with Global Warming Potential split into fossil, biogenic, and land-use change. If your audience is time poor, lead with GWP-total and GWP-fossil, then show resource use and waste for credibility (EPD International, 2024; CEN EN 15804+A2, 2019).

Validity, expiry, and updates

PCRs typically have a 5‑year validity window. EPDs themselves are usually valid for 5 years. When a PCR updates, existing EPDs remain valid until their own expiry, then must renew under the newer rule set. Plan portfolio refreshes around those cycles to avoid last‑minute scrambles (EPD International, 2024) (IBU, 2024).

Want the latest EPD news?

Follow us on LinkedIn to get relevant updates for your industry.

What protective-coating PCRs nail down

A good coatings PCR will specify functional or declared units, often 1 m² of coated surface at a defined dry film thickness and service life scenario. It clarifies required modules, typically A1 to A3 mandatory, A4 and A5 often required for coatings because transport, application equipment, thinning, and overspray can move the needle. It also sets how to treat maintenance repaints and biogenic carbon, plus the data quality period for your reference year.

Common pitfalls that stall reviews

Shortlists save time.

- Declaring per kilogram when the PCR requires per square meter at a specified coverage rate. Reviewers will send this back.

- Ignoring system-level impacts. Many protective systems are primer plus midcoat plus topcoat. The PCR may require declaring the full system.

- VOC confusion. TVOC limits belong in health declarations. For EPDs, the PCR wants how solvents and water affect inventory and A5 emissions, not a marketing “zero VOC” claim.

- Old background datasets. If your PCR requires data within a defined vintage, out‑of‑date datasets can trigger extra sensitivity runs.

How to pick a program operator

Publish where your buyers look. For US building projects, UL and NSF are widely recognized. In Europe, IBU and program operators within the ECO Platform ecosystem are common. Norway‑centric portfolios often appear under EPD Norway. Newer operators like Smart EPD and EPD Hub also host construction EPDs. The goal is simple. Fast review, clean formatting, easy searchability in public portals.

Data your LCA team will request

Have this ready to move quickly.

- Resin, pigment, filler, and additive recipe ranges for each SKU or formulation cluster.

- Plant‑level utilities, yields, waste, and packaging for a defined 12‑month reference year. Prospective EPDs are possible for brand‑new lines, but they must be updated once a full year of data exists.

- Application parameters. Recommended film build, coverage, thinning ratios, typical equipment, cure requirements, and maintenance intervals.

- Upstream specifics. Solvent types, bio‑based content if relevant, and transport distances.

A white‑glove partner will collect most of this directly from production, QA, purchasing, and EH&S so senior R&D is not stuck hunting utility bills.

A quick route for teams searching “pcr for protective coatings”

Start with your market and use phase. If your coating protects structural steel or concrete in buildings or infrastructure, check coatings Part B under EN 15804 for Europe or a coatings PCR aligned with ISO 21930 in North America. For floors, look for resinous floor coatings PCRs. For powders, pick the powder‑coatings PCR. For roof liquids, choose a roof‑coatings PCR. Validate that the chosen PCR is current and gives you a 5 year runway before it expires (EPD International, 2024).

What this means commercially

An EPD aligned to the same PCR family your competitors use removes hidden penalties in carbon accounting and keeps your products in the spec conversation. Sales can approach projects that would otherwise exclude you. The cost of doing one right is often dwarfed by a single mid‑sized win. That is the real ROI, not another green badge.

Tieing it together

Pick the correct coatings PCR, confirm its validity window, and publish with an operator your specifiers trust. Keep data collection lean, predictable, and verifiable. Do this and your protective system is ready for LEED v5‑era bids without drama. It is definately achievable with the right gameplan.

Frequently Asked Questions

Are EPDs invalid when the underlying coatings PCR expires

No. A PCR update does not cancel an already published EPD. Your EPD remains valid until its own expiry, then must renew against the newer PCR. Typical EPD validity is 5 years (EPD International, 2024) (IBU, 2024).

What if my coating is part of a multi‑layer system

Many PCRs for protective coatings expect you to declare the full system at the specified film build and coverage. Provide mass per m² and maintenance intervals where required so A5 and B-stage impacts are accounted for.

Do I need to model application losses and thinning

Usually yes. Coatings PCRs often require A5 modeling of overspray, solvent addition, application equipment electricity, and cleaning. These are not optional marketing claims, they are inventory requirements.

Which indicators should sales highlight from the EPD

Lead with Global Warming Potential total, then fossil and biogenic splits where reported under EN 15804+A2. Buyers also scan resource use and waste metrics for a sanity check of credibility (EPD International, 2024).

How often do PCRs refresh and how do we plan

Plan on a 5‑year PCR validity cycle, then budget a portfolio refresh that rolls expiring EPDs into the new rules. Avoid a cliff by staggering renewals across quarters (EPD International, 2024).