PCRs for Lighting Systems, Decoded

If you make luminaires or lighting controls, the right Product Category Rules determine whether your Environmental Product Declaration lands smoothly on a specifier’s desk or stalls in review. Here’s the fast path through a tricky landscape, so your team spends less time hunting documents and more time shipping product.

PCR basics for lighting in one minute

A Product Category Rule is the rulebook that tells you how to model, measure, and format an LCA so the final EPD is apples to apples. For lighting systems, PCRs set scenarios for use-phase energy, reference service life, maintenance, and end of life. Pick the wrong rulebook and comparability breaks.

Lighting is a special case because the use phase usually dominates. Globally, lighting draws about 12% of end‑use electricity and smart controls plus LEDs can cut that in half, which is exactly why the PCR’s B6 modeling assumptions matter so much (IEA 4E, 2024).

The rulebooks you will actually see

Today there are two main paths manufacturers use when searching for a “PCR for lighting systems.”

- EN 15804 path within construction EPD programs. Many luminaire EPDs are published under the International EPD System using the core PCR 2019:14 for Construction Products, sometimes alongside a complementary Part B when available. Version 1.3.4 of 2019:14 reached its sunset on June 20, 2025, with programs shifting users to the updated release, so check the version called on your competitor set before you start (EPD International, 2025).

- PEP ecopassport path for electrotechnical products. PEP uses an ISO 14025 PCR plus Product Specific Rules. PSR0014 explicitly covers luminaires and has been live since July 13, 2023, which many European lighting brands follow for portfolio rollouts (PEP ecopassport PSR0014, 2023).

A North American, lighting‑specific Part B PCR is also being developed in the Smart EPD program in collaboration with industry groups such as NEMA, intended to align regionally with global norms.

EN 15804 vs PEP for luminaires

Think of EN 15804 as the construction universe playbook, and PEP as the electrotechnical playbook. Both are ISO 14025 type III declarations, but each has its own modeling heritage and acceptance patterns by region and database. If your sales rely on ECO Platform recognition or EN 15804‑centric procurement, the EN path is often safer. If you sell into electrotechnical channels or France in particular, PEP can be a strong fit. When in doubt, scan how peer luminaires are published in your target markets and copy the center line.

Regulators keep raising the floor on efficiency too. Minimum energy performance standards now cover almost 80% of global lighting energy consumption, rising above 90% in the United States, Europe, and China, which pushes specifiers to expect transparent and comparable energy scenarios in EPDs (IEA Lighting, 2025).

Ready to navigate PCRs for your lighting products?

Follow us on LinkedIn for insights that help you get spec'd and streamline your EPD process.

What modules matter for lighting EPDs

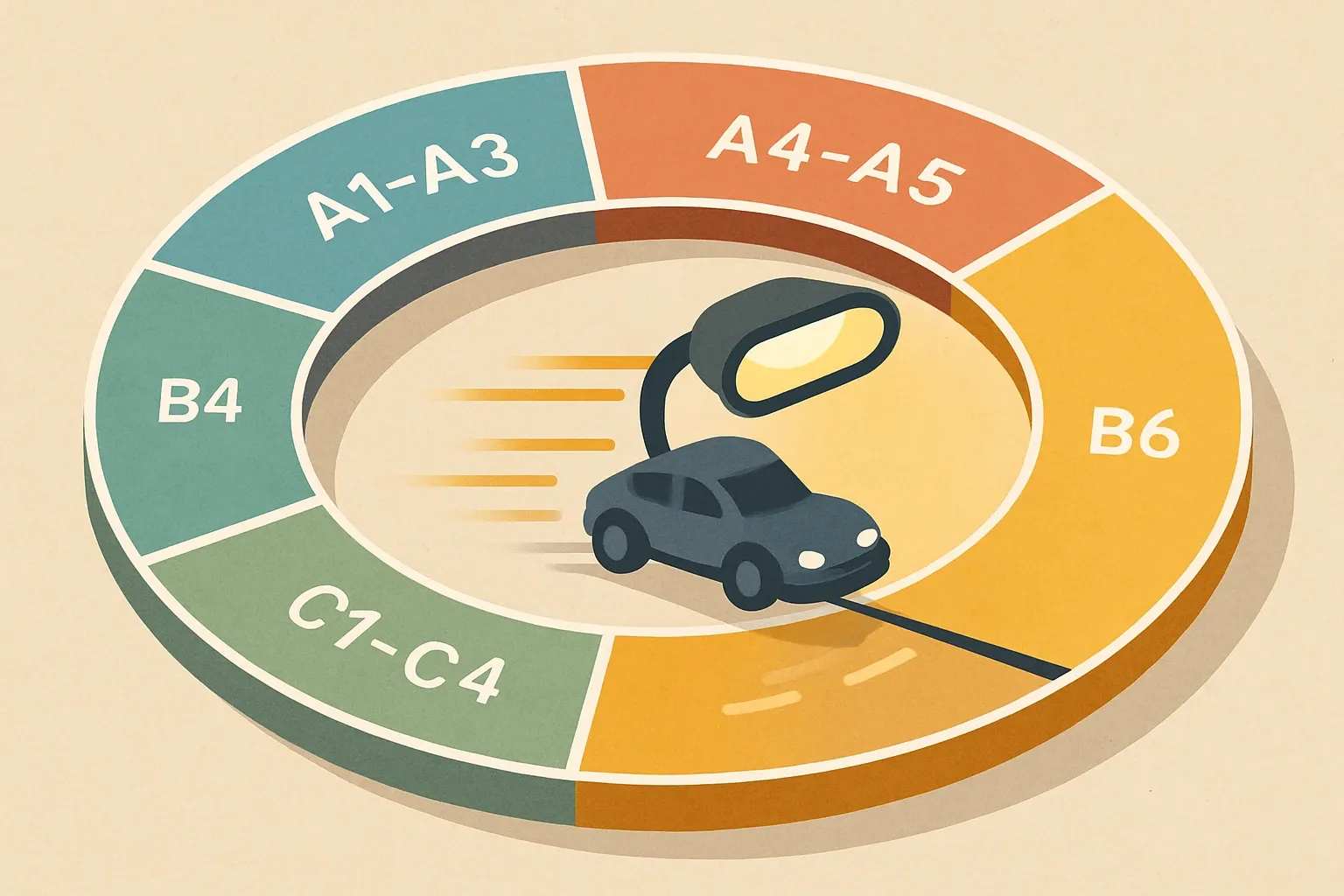

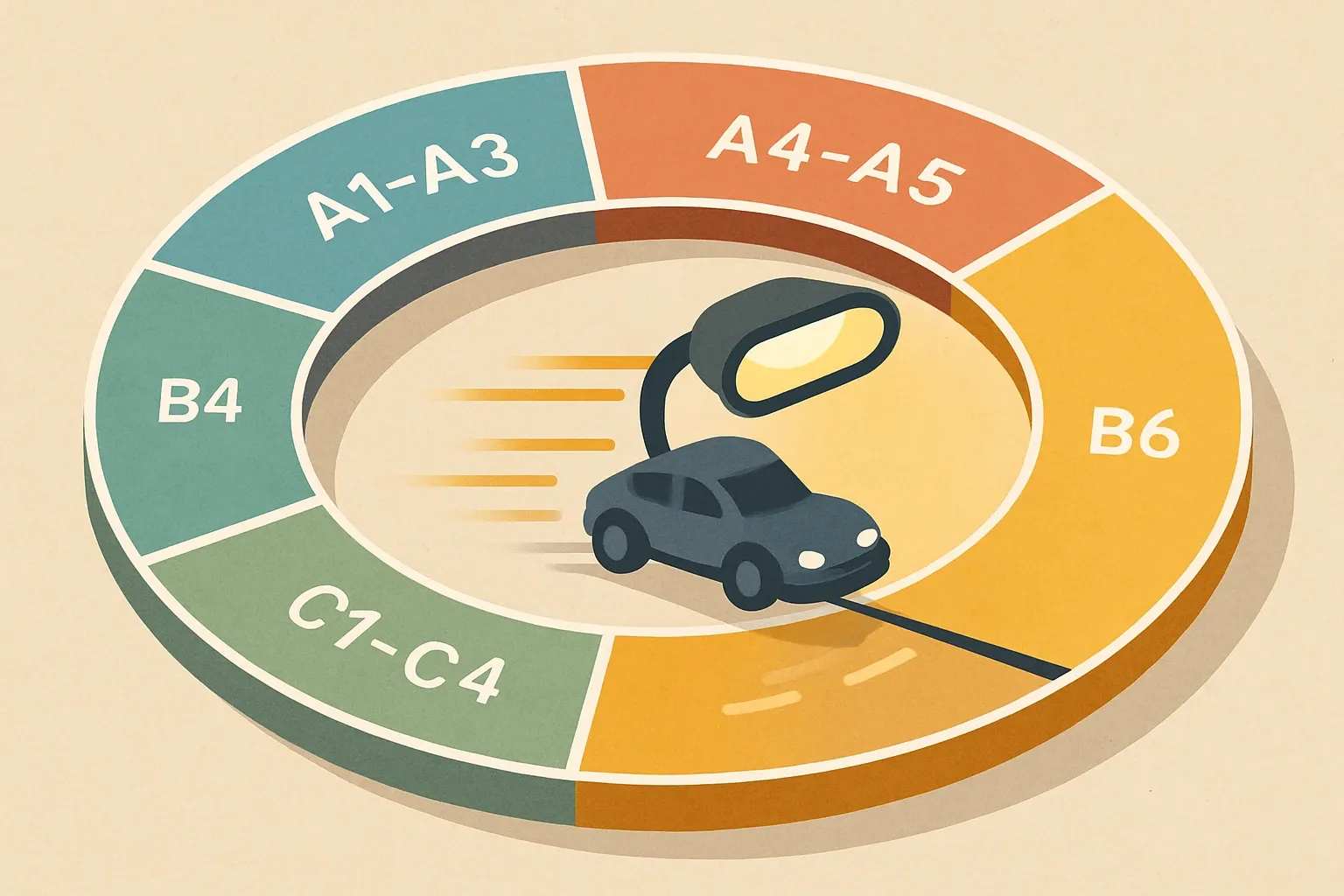

Most lighting PCRs require or guide scenario modeling for these life‑cycle stages.

- A1 to A3 production and A4 to A5 construction, where materials, drivers, optics, and packaging show up.

- B6 operational energy with specified hours of use, control strategy, standby power, and grid mix. This is the heavy hitter for many luminaires.

- B4 replacement if the driver or LED board is modeled to fail before the reference service life. Getting this wrong can skew results more than any recycled cardboard choice.

- C1 to C4 end‑of‑life, plus potential module D benefits for material recovery, depending on the rulebook.

A PCR is the rulebook of Monopoly. Ignore it and the game falls apart.

How to choose the right PCR for your product line

Start with your commercial goal. If you need acceptance in EN 15804‑driven building databases, anchor on EN 15804 with the current 2019:14 release and any active Complementary Part B for luminaires available through your operator. If your customers and sales partners ask for PEP references, PSR0014 is the straight line.

Then check comparability. If the top three competitors for your roadway fixtures publish under PEP, following PSR0014 improves head‑to‑head clarity. If they use EN 15804 with B6 scenarios tied to office hours and presence detection, mirror that logic so bids are genuinely comparable. We see teams win time when they pick the same yardstick as their market.

Data you will wish you had on day one

Gather these items before the LCA kicks off, so verification moves quickly and your experts can focus on quality not chasing spreadsheets.

- Declared unit choice and reference service life that matches the PCR you will use

- Rated power per SKU, driver efficiency, standby consumption, and control profiles by application

- Lumen maintenance assumptions and any replaceable subassemblies, with realistic B4 replacement logic

- Annual hours and occupancy or daylight control scenarios used by your sales team or common in bids

- Packaging and transport modes by ship‑to market

- End‑of‑life assumptions for metals, plastics, and WEEE flows

Smart modeling choices that avoid rework

A crisp PCR alignment avoids painful updates. If the EN 15804 program you choose updated its PCR version this year, lock to the newest version at project start and document the B6 scenario in plain language inside the EPD. If you plan a control‑heavy story, include a variant that represents common controls off the shelf and another that shows baseline on a simple schedule. That way your product can be specified across projects without recalculating every time someone swaps sensors.

Timelines, expiries, and how to stay current

EPDs usually carry a five‑year validity period, and programs expect updates within that window if results shift materially. A PCR can expire during your EPD’s life, yet your EPD remains valid until its own end date as long as it met the rules in force at verification (EPD International FAQ, 2025). Build a light annual check‑in to confirm that your PCR version, use‑phase scenario, and grid mix still reflect reality. It is a small habit that saves big scramble later.

Where LEED v5 and public buyers are headed

Specs are moving toward lower‑carbon options with transparent use‑phase energy and credible service life. That makes well‑documented B6 and B4 modeling a commercial asset, not just a compliance box. When a contractor can plug your luminaire EPD into their model without extra assumptions, your product becomes the easy yes. It also means sales is less likely to avoid opportunities just because an EPD felt like weeks of internal wrangling.

Quick path forward

Pick the rulebook your buyers expect, mirror competitor conventions for true comparability, lock scenarios early, and gather the usage data that actually drives results. If fluorescent is spelled flourescent somewhere in internal docs, fix that too. Above all, make the data intake painless so the smartest people on your team can stay focused on the product rather than paperwork.

Frequently Asked Questions

Which PCR should a U.S. luminaire manufacturer choose in 2025?

If your customers or databases require EN 15804 alignment, use the International EPD System’s PCR 2019:14 with the latest version and any luminaires‑specific Part B available through your operator. If you sell primarily into electrotechnical channels, PEP ecopassport PSR0014 for luminaires is a strong alternative. Check what competitors use to maintain comparability.

Do lighting EPDs have to include operational energy in B6?

Most lighting rulesets require B6 scenario modeling with defined hours, control profiles, and grid mix because use‑phase energy typically dominates impacts. The exact scenario and sensitivity ranges are set by the applicable PCR or PSR.

How long is a lighting EPD valid?

Five years is typical for program operators, with updates expected if results change materially. A PCR may expire during that period, but the EPD remains valid until its own end date as long as it was verified to a valid rule at the time (EPD International FAQ, 2025).