Bio‑Based Insulation PCRs, explained

Cellulose, wood fiber, hemp, cork, even straw. If you make bio‑based insulation, the right PCR decides how you model biogenic carbon, moisture, density, and end‑of‑life. Choose well and you publish quickly with fewer revision loops. Choose poorly and verification drags, specs slip, and rivals set the comparison rules.

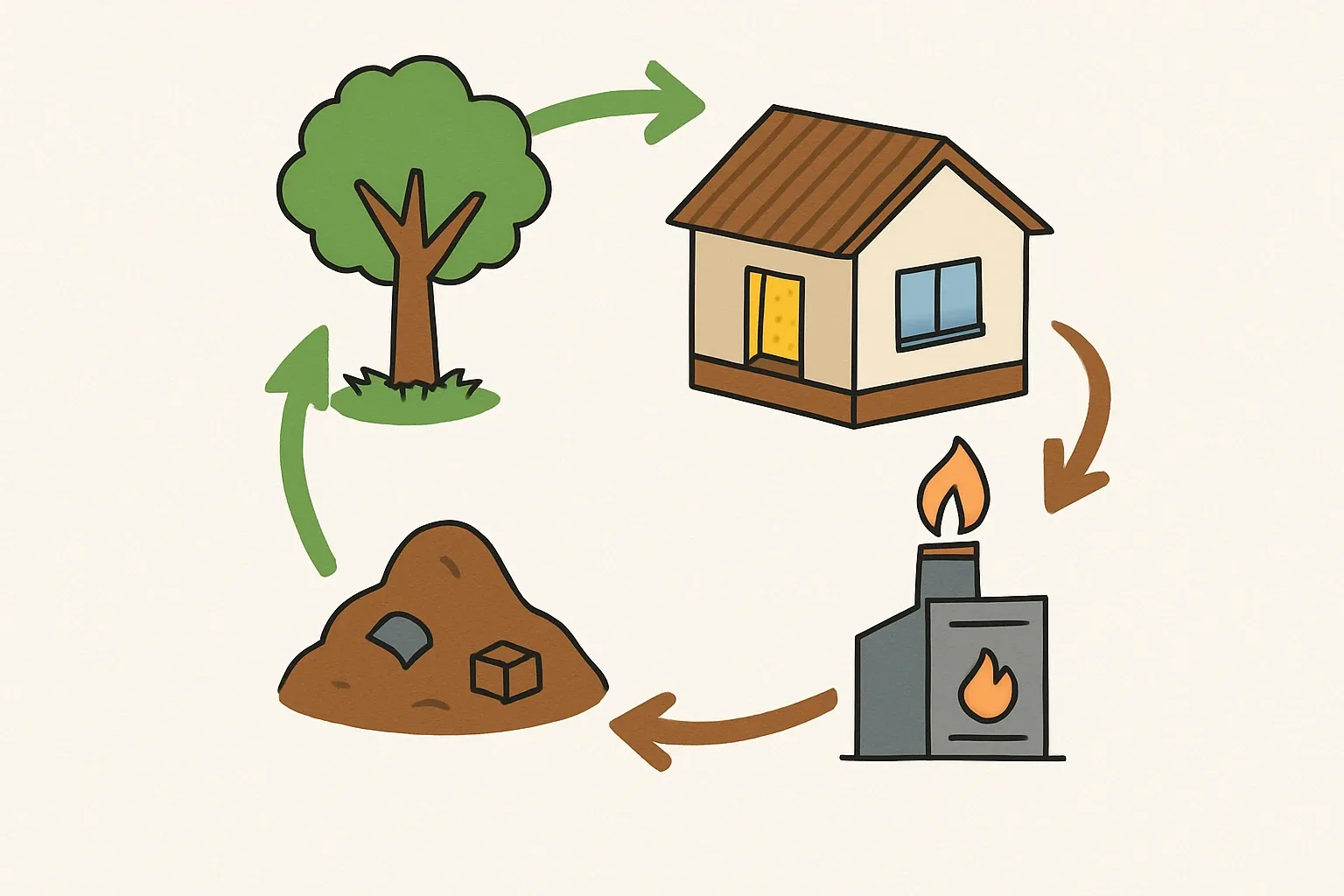

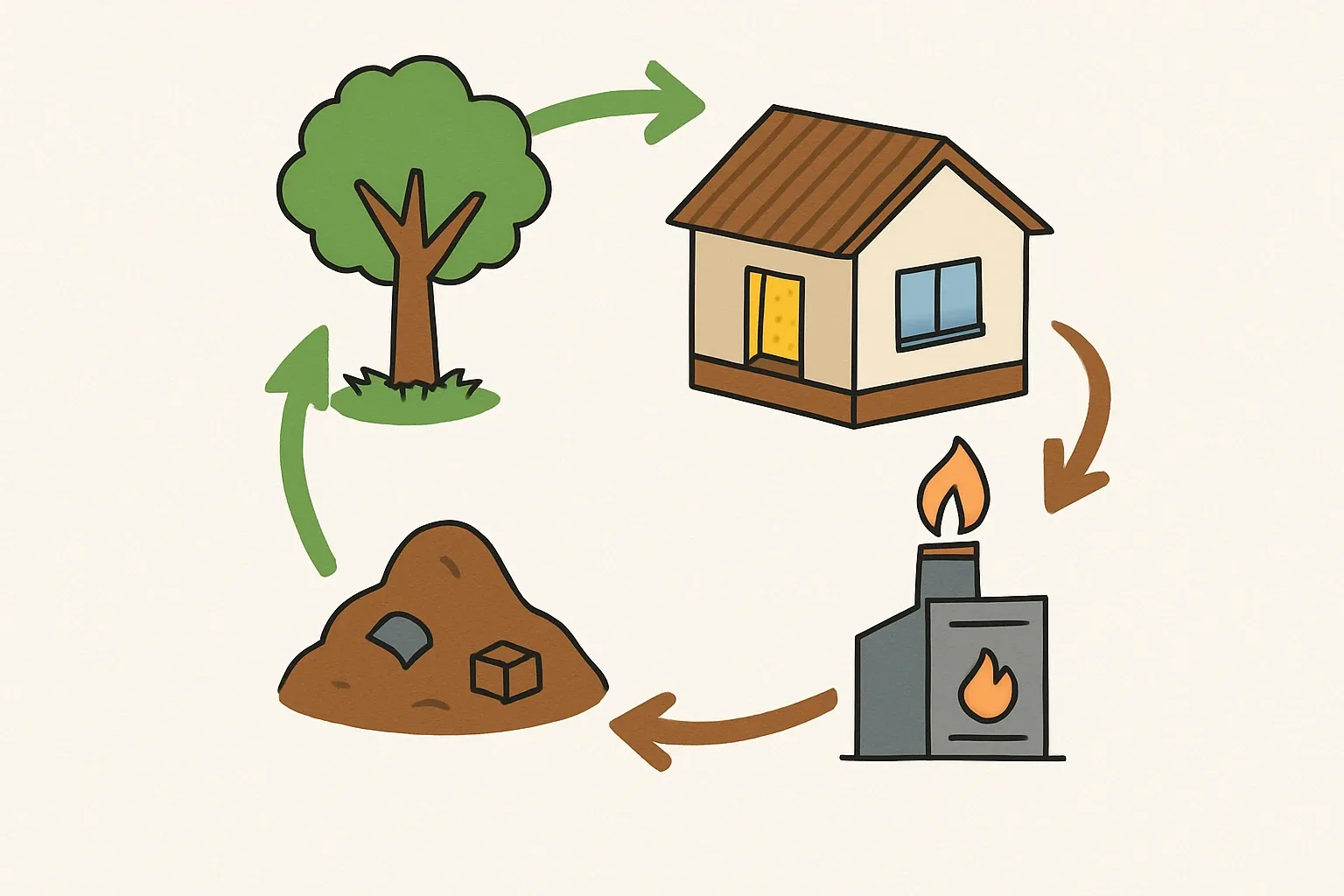

PCRs for bio‑based insulation in one picture

A PCR is the rulebook of Monopoly. Ignore it and the game falls apart. For bio‑based insulation, the PCR you choose sets the declared unit, data scope, scenarios, and biogenic carbon accounting that end up in your EPD.

Across Europe, most construction products use EN 15804 A2 as the umbrella. For thermal insulation, the International EPD System points to a complementary PCR aligned with EN 16783 that is registered and currently valid until 2030‑04‑07 (EPD International, 2025) (EPD International c‑PCR Thermal insulation, 2025).

North America vs Europe, fast

In North America, many insulation EPDs follow ISO 21930 with program‑operator Part A plus a Part B such as UL Solutions’ Building Envelope Thermal Insulation or UL Part B for Mechanical, Specialty, Thermal, and Acoustic Insulation. NSF’s public listings show active EPDs validated to these PCRs with five‑year validity windows (NSF, 2025). In Europe, IBU applies Part A and product‑specific Part B documents under EN 15804 A2, with an updated Part A published 30 April 2024 and a six‑month transition that ended 29 October 2024 (IBU, 2024).

What “A2” changes for bio‑based materials

Specifiers now expect the A2 set of indicators. National databases confirm that A2 uses 19 environmental impact categories in building assessments, which include the expanded climate change splits and mandatory end‑of‑life reporting for C1 to C4 plus Module D (NMD, 2025) (NMD, 2025). That means your EPD cannot stop at cradle‑to‑gate if you want to show credible, comparable results for wood fiber or cellulose.

Biogenic carbon, handled the grown‑up way

A2 asks you to separate fossil, biogenic, and land‑use change contributions, then show a total. For bio‑based insulation, that forces you to document carbon storage in A1 to A3 and potential release at end‑of‑life. Get your moisture content, volatile additives, and binder shares right or your carbon math walks on stage with mismatched shoes.

Which PCR fits my product

Start with how the product is used. Envelope cavity batts, blown‑in cellulose, wood fiber boards, cork boards, hemp batts, and in‑situ sprays typically map to thermal insulation PCRs. Acoustic underlay or duct wraps can fall under mechanical or specialty insulation PCRs in North America. When products straddle use cases, follow the dominant application and what competitors use so your buyers can compare apples to apples.

Struggling with PCRs for bio-based insulation?

Follow us on LinkedIn for insights that help you navigate rules and enhance your project specifications.

Declared unit and service life shortcuts

Insulation PCRs usually fix the declared unit at 1 m² delivering RSI 1 m²·K/W, often with a reference service life like 75 years. Treat this as a camera lens that normalizes thickness across materials. If your product is sold by thickness or density, include a simple mapping table in the project report so reviewers can trace your math without a scavenger hunt.

End‑of‑life scenarios that fit bio‑based reality

Model realistic routes. Cellulose and wood fiber often go to energy recovery in many markets, while some boards are landfilled or recycled as composite feedstock. If you claim composting, back it up with local practice and contaminants screening. Keep adhesives, flame retardants, and facers visible in the inventory so reviewers do not fish for hidden burdens.

Timelines and expiries to plan around

Most program operators set EPD validity at five years. Plan a mid‑cycle data check so you do not stumble into a forced update if indicators worsen by more than 10 percent during validity (EPD International, 2025). The core construction PCR at the International EPD System moved from version 1.3.4 to 2.0.x with a sunset on 20 June 2025 and a temporary publication timeline extension to up to 10 working days during the rush period (EPD International, 2025) (EPD International transition guidance, 2025). The thermal insulation c‑PCR itself stays valid through 2030‑04‑07 so you are not switching horses mid‑ride (EPD International c‑PCR Thermal insulation, 2025).

If there is no perfect PCR match

Two workable paths. Use the mainstream construction PCR with the thermal insulation complement where applicable, or work with a program operator to create or revise a Part B. IBU publicly states it will co‑develop missing Part B documents with industry, though you must invest time and expertise to do it right (IBU, 2024). New standards work is also active around insulation subtypes, so scanning the pipeline can save a redo later in the cycle (SIS EN 16783, 2024).

Practical data checklist for bio‑based insulation

- Sawmill residue share or fiber origin by country and certification status.

- Additives by mass percent, including fire retardants and binders.

- Density range and moisture content at declared conditions, plus packaging.

- Plant‑level utilities and fuels for one reference year, including biomass fractions.

- End‑of‑life split by route that matches actual markets you sell into.

What specifiers will ask in 2025

They will look for A2 reporting breadth and clear biogenic carbon handling. They will also check that your PCR choice matches peer EPDs so their models do not break. If your team can gather clean plant data without hijacking production leaders for weeks, verification goes faster and you get to the bid window sooner. Otherwise, the enviromental paperwork starts to run the show.

A quick map for “PCR for bio based insulation” seekers

If your product is mainly thermal insulation in Europe, start with EN 15804 A2 under the insulation c‑PCR tied to EN 16783 and verify it is still within its 2030‑04‑07 validity window (EPD International c‑PCR Thermal insulation, 2025). If you publish in North America, check whether UL’s Building Envelope Thermal Insulation or UL Part B for mechanical and acoustic insulation better fits the use case, then confirm your operator accepts ISO 21930 alignment for cross‑market comparability. Keep one eye on operator notices so you do not miss version sunsets or extended publication lead times (EPD International, 2025) (EPD International transition guidance, 2025).

Frequently Asked Questions

What PCR should a cellulose or wood fiber batt use for a European EPD in 2025?

Use EN 15804 A2 as the umbrella with the complementary thermal insulation PCR aligned to EN 16783 that is registered and valid until 2030‑04‑07 at the International EPD System (EPD International c‑PCR Thermal insulation, 2025).

How long is an EPD valid and do we need to update mid‑cycle?

Most programs set five‑year validity. You must update during validity if any reported indicator worsens by more than 10 percent compared to the published data (EPD International, 2025).

Does EN 15804 A2 really require more indicators for insulation EPDs?

Yes. National guidance confirms A2 assessments use 19 environmental impact categories and require end‑of‑life and Module D reporting, which affects bio‑based materials directly (NMD, 2025) (NMD, 2025).

Is there a North American PCR dedicated to bio‑based insulation only?

Not typically. In practice, bio‑based products map to Building Envelope Thermal Insulation or Mechanical, Specialty, Thermal, and Acoustic Insulation Part B rules under ISO 21930. Check your operator’s current Part B scope and competitor EPDs to align.

What changed around construction PCR timing in 2025?

International EPD System moved to PCR 2019:14 version 2.0.x with a final sunset for v1.3.4 on 20 June 2025 and a temporary extension of publication timelines to up to 10 working days during the transition (EPD International, 2025) (EPD International transition guidance, 2025).