PCRs for Insulation Materials, Explained

If insulation is your product, the right PCR is your playbook. Choose well and your EPD lands fast, aligns with what specifiers expect, and avoids costly rework. Choose poorly and you chase data, redo models, and miss bid windows. Here is the map, without the maze.

What a PCR actually does for insulation

A Product Category Rule is the rulebook of Monopoly. Ignore it and the game falls apart. For thermal insulation, the PCR sets scope, datasets, allocation methods, reporting rules, and what counts as good enough evidence.

PCRs sit underneath ISO 14025 and either EN 15804 or ISO 21930, which define how construction-product EPDs are structured. Most program operators set EPD validity at 5 years, so teams plan on a refresh cadence that fits sales cycles, not just compliance windows (IBU, 2024) (IBU, 2024).

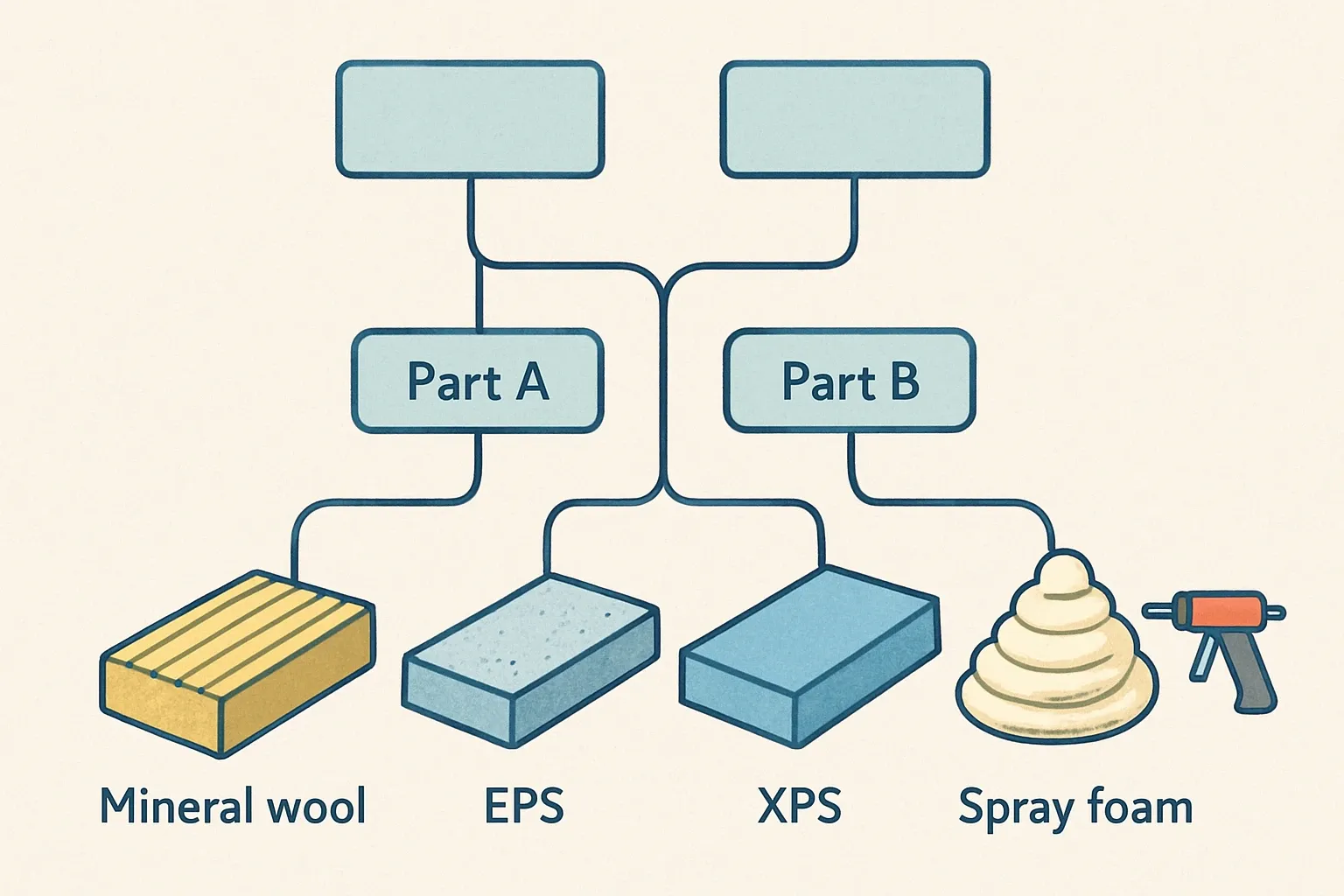

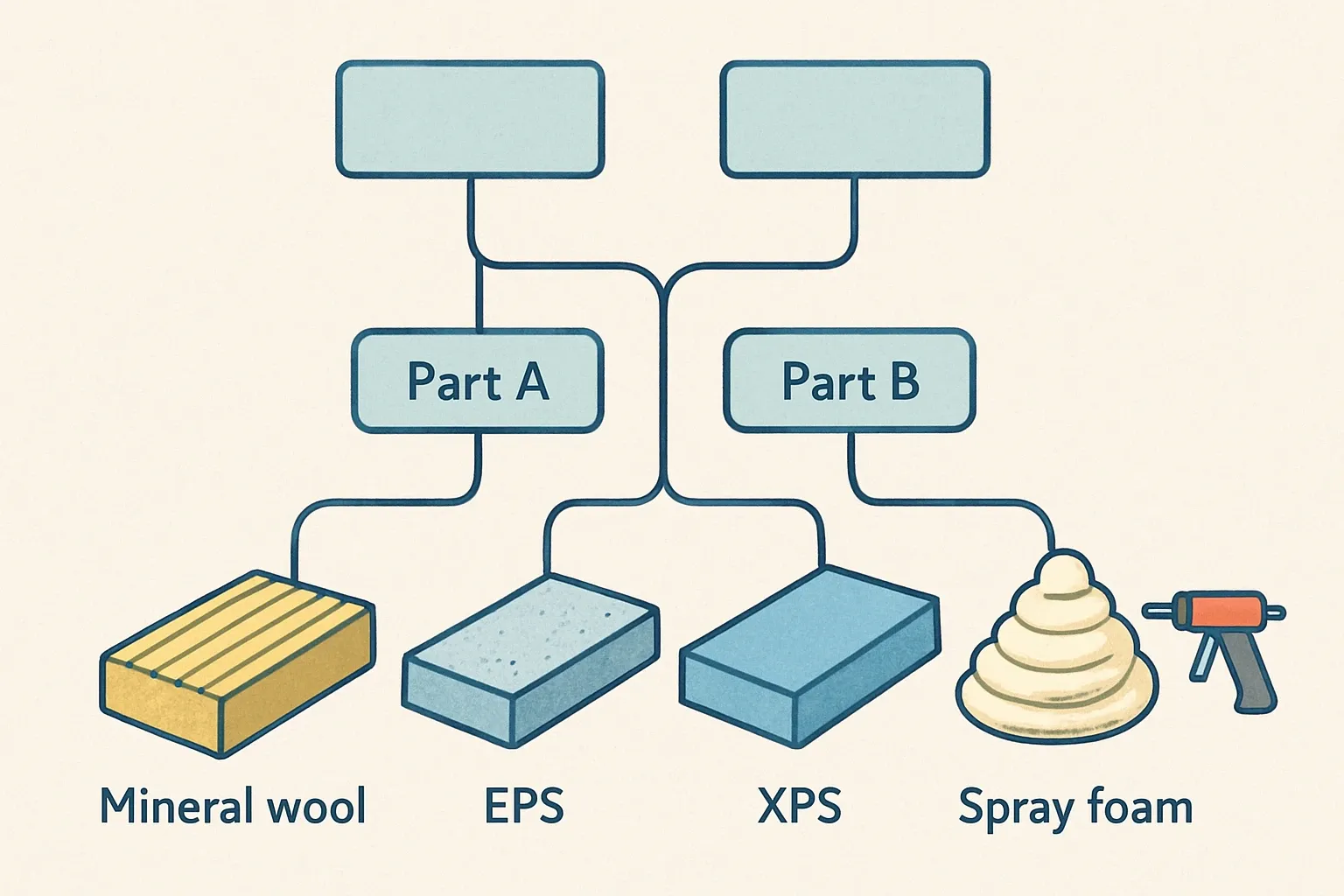

Which PCRs apply to common insulation types

Mineral wool, fiberglass, and stone wool usually use construction-product PCRs with a Part B for insulation. In Europe these are tied to EN 15804 and often reference EN 16783 for insulation specific rules. Foam plastics such as EPS, XPS, polyiso, and spray foam also rely on an insulation Part B that calls out blowing agents, lamination, and trimming losses.

If you are searching for a “pcr for insulation materials”, expect to find a Part A general construction PCR paired with a Part B that is product family specific.

EN 15804 or ISO 21930 as your backbone

In the EU, EN 15804+A2 is the baseline. It expanded the core environmental indicators to 13 that must be reported in construction EPDs, which is a material change from the older A1 version (CEN EN 15804+A2, 2019). In North America, many EPDs follow ISO 21930 with PCRs harmonized to 14025. Either route works, but mixing frameworks mid portfolio creates confusion for specifiers.

Program operator choices and what they change

Program operators like IBU, EPD International, UL Solutions, and Smart EPD publish insulation EPDs. Their structure is similar, yet administrative details differ. For example, UL’s program instructions confirm the common 5 year validity for published EPDs, which affects renewal plans and marketing calendars (UL Solutions, 2024) (UL Solutions, 2024). EPD International’s Programme Instructions also define PCR review cycles, commonly 5 years, which is why teams watch both EPD and PCR dates together (EPD International, 2024) (EPD International, 2024).

Are you ready to streamline your EPD process for insulation materials?

Follow us on LinkedIn for insights on PCRs that help you avoid costly mistakes and win more tenders.

Data you need on day one

Strong insulation EPDs start with clean operations data. At minimum plan for one full calendar year of production, utilities, raw materials, waste, and transport to the plant gate, since EN 15804 requires at least 12 months of representative manufacturing data for A1 to A3 modelling (CEN EN 15804+A2, 2019). A prospective EPD is possible for new lines with a shorter window, but it will need an update once a full year is available.

Helpful checklist to keep momentum:

- Plant level utilities by month, metered where possible

- Bill of materials with suppliers and transport modes to site

- Scrap and trimming rates, especially for foam boards

- Packaging specs, palletization, and average load factors

Boundaries that matter in insulation PCRs

Insulation PCRs almost always require A1 to A3. Many also ask for A4 and A5 when installation drives emissions or waste, for example with adhesive use or cutting loss. If service life or thermal performance is central to claims, B modules and declared R values must be consistent with the PCR’s functional unit and reference service life.

Foam plastics and blowing agents

For EPS, XPS, polyiso, and spray foam, PCRs expect transparency on the blowing agent type and loss rates. Blowing agent selection can shift A1 to A3 results dramatically, so documenting the actual formulation and venting practice is not optional. Some PCRs call for separate scenarios if multiple blowing agents are used across plants in the same product family.

PCR expiry does not cancel an EPD

When a PCR expires, an existing EPD does not vanish. It stays valid until its own end date, then the next renewal must use the updated or successor PCR. Many programs review or renew PCRs on roughly a 5 year cycle, so teams track both clocks to avoid last minute scrambles that delay submittals (EPD International, 2024). Having an older yet still valid EPD is usually fine in bids unless it is within a few months of expiring.

Overlapping rules and how to choose

When two PCRs look applicable, pick the one most common in your competitive set to keep apples to apples. Check three filters before deciding. First, confirm the functional unit matches how buyers compare products, typically 1 square meter at declared thickness for a thermal resistance target. Second, compare module requirements, since some Part Bs require installation adhesives or ancillary materials to be modelled. Third, look at timing, because a PCR that expires next quarter creates re work.

LEED v5 and why it still matters

LEED v5 is progressing and continues to reward product specific, third party verified EPDs. Even with policy changes at the federal level, project teams still need defensible carbon accounting, and an insulation EPD keeps your product in consideration rather than forcing modelled penalties during design.

Picking the partner for speed and quality

Manufacturers win when the LCA partner makes data collection painless across plants and shifts. Ask how they handle messy ERP exports, supplier questionnaires, and transport modelling without consuming the time of your most valuable people. Methods that automate the wrangling let R&D and plant managers stay focused on throughput while the EPD moves forward. That is how insulation portfolios recieve EPDs fast without cutting corners.

The short version

Insulation PCRs are not mysterious. Choose the correct Part B aligned with EN 15804 or ISO 21930, gather one solid year of data, model the installation reality, and watch the PCR and EPD clocks together. Do this and your “pcr for insulation materials” search turns into a publishable, trusted EPD on a timeline that helps win specs, not miss them.

Frequently Asked Questions

How long is an insulation EPD typically valid under most programs?

Five years in most programs, with renewal using the current PCR version at that time (IBU, 2024) (IBU, 2024).

What production data period should we plan for A1 to A3?

Plan for one full year of representative manufacturing data, which aligns with EN 15804+A2 requirements for data representativeness (CEN EN 15804+A2, 2019).

Does a PCR expiring make our current EPD invalid immediately?

No. The EPD remains valid until its own end date, then the renewal must use an updated or successor PCR (EPD International, 2024) (EPD International, 2024).