Resinous healthcare flooring in Denmark: who has EPDs?

Hospitals in Denmark face tighter climate limits from July 1, 2025. If your resin floors arrive without an EN 15804 EPD, project LCAs get harder, bids slow, and your product risks being swapped. Here’s the fast read on which resinous players show up with declarations, why that matters under BR18, and how to move from “we’ll get to it” to EPD‑ready without stressing your ops team.

Denmark’s 2025 climate rules raise the bar

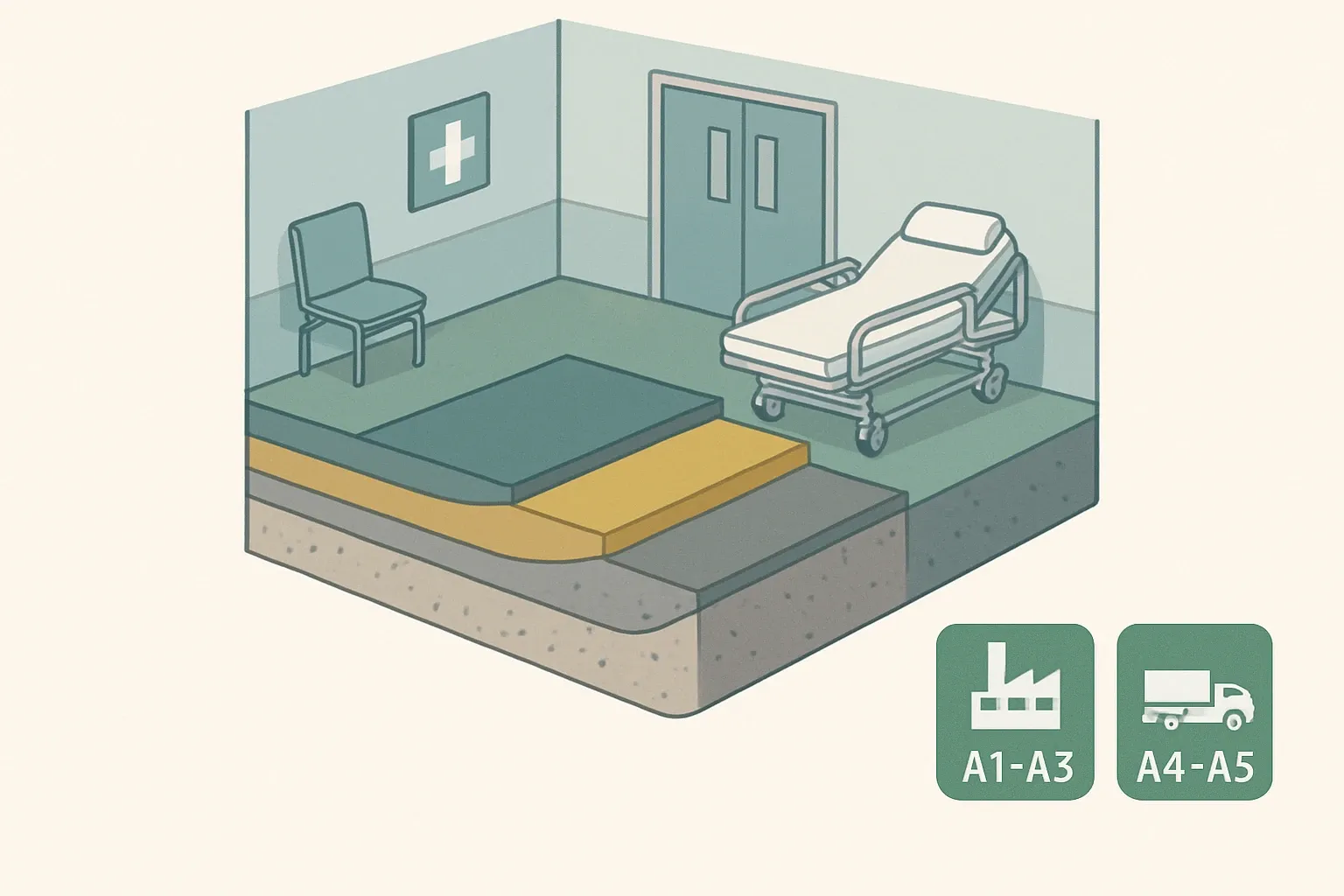

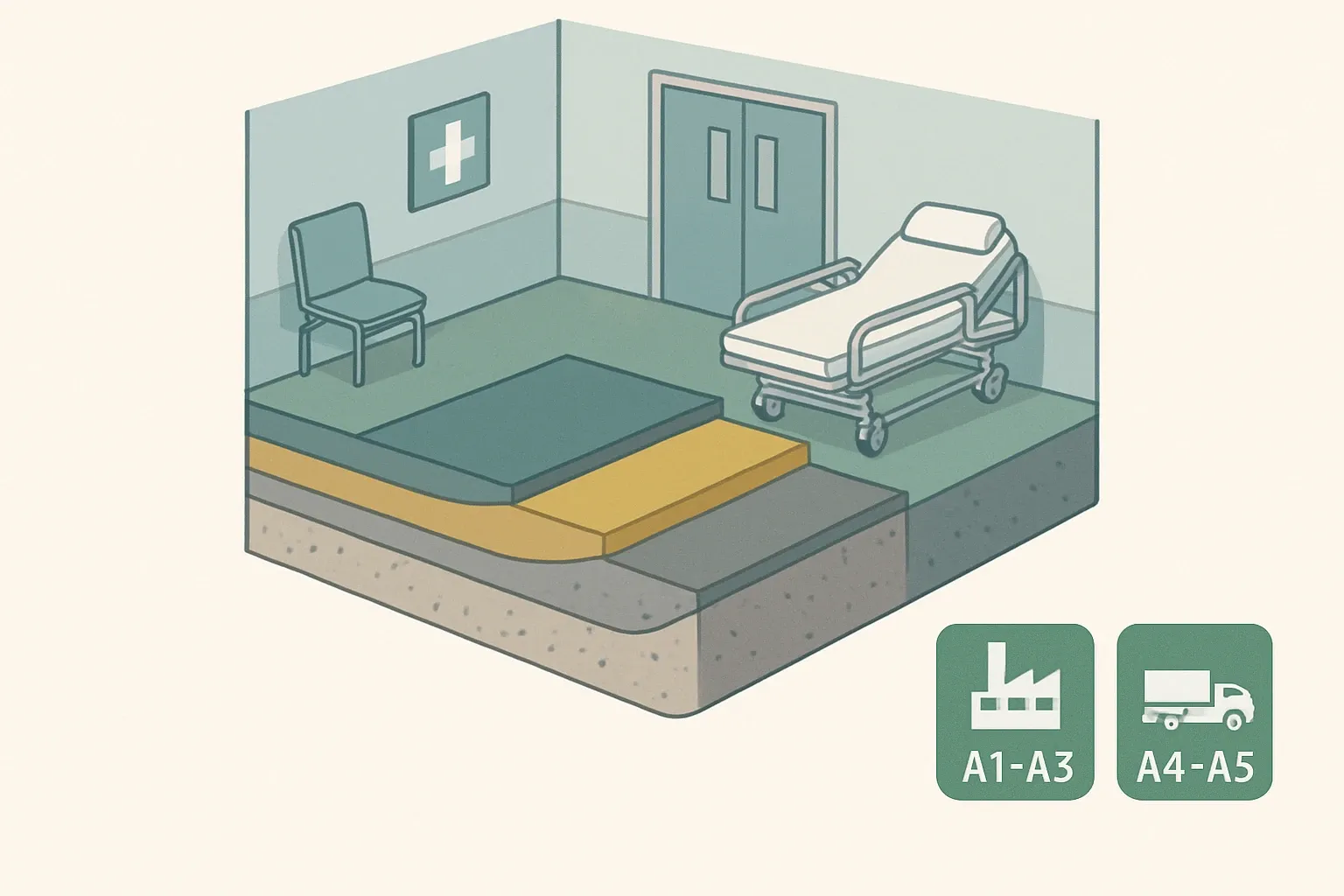

From July 1, 2025, Danish building permits trigger stricter CO2e limits by building type. Institutional buildings that include hospitals must document LCAs and meet a differentiated limit, and construction process emissions have a separate 1.5 kg CO2e/m²/yr cap for modules A4–A5 (Social- og Boligstyrelsen, 2025) (Social- og Boligstyrelsen, 2025). The updated BR18 pages confirm the added A4–A5 limit and how mixed‑use areas are handled via area‑weighted calculations (BR18, 2025) (BR18, 2025).

Why resinous floors fit healthcare LCAs

Resinous floors are seamless, hygienic, and repairable in place. That reduces interfaces, simplifies cleaning protocols, and helps maintenance LCAs. They also offer ESD and chemical resistance for labs and imaging spaces. All of that shows up in the bill of materials and use‑phase assumptions that feed your project LCA.

The competitive map in Denmark

Here’s how the main resinous players show up on EPDs today in the Danish healthcare context.

- Flowcrete Denmark, part of Tremco CPG. Local product pages reference EPDs for epoxy groups and list EPD links in the technical documentation library.

- Sika. Multiple Sikafloor components and systems list EN 15804 EPDs independently verified by IBU on product pages, including comfort and ESD topcoats.

- Mapei Denmark. Mapefloor polyurethane‑cement and PU membrane systems carry current EN 15804+A2 EPDs published in 2024–2025 with European or Nordic scope (EPD International, 2025) (EPD International, 2025).

- Stonhard Denmark. Resinous systems for healthcare and labs with multiple current, third‑party EPDs covering epoxies, urethanes, primers, and sealers.

None of this says who has the “greenest” floor. It tells specifiers who arrives with verified, machine‑readable data that drops into LCAbyg and project LCAs without friction.

Want the latest EPD news?

Follow us on LinkedIn to get relevant updates for your industry.

What EPD coverage means for hospital bids

- Faster LCA compliance. A verified EN 15804 EPD avoids generic penalties in Danish LCAs, especially when A1–A3 and A4–A5 must be declared.

- Fewer substitution risks. If your system has no EPD, teams often model a conservative value. That can make your floor look heavier on carbon than a competitor that simply documented early.

- Portfolio resilience. Limits tighten again in 2027 and 2029. Being EPD‑ready now reduces rework later.

Picking the right PCR and operator for resin floors

For resin systems, you’ll typically declare under EN 15804 with a resinous flooring or coatings Part B rule set. Good operators ensure conformance, digital export, and ECO Platform recognition so Danish project tools can ingest your data cleanly. Expect to capture A1–A3, transport, packaging, installation auxiliaries, waste, declared unit per m² at a reference thickness, service life assumptions, maintenance, and end‑of‑life scenarios. Keep your BoM and recipes traceable to speed verification.

A 30–60 day play to get EPD‑ready

- Map the competitive PCR path. Align to the rule set your competitors used so buyers can compare apples with apples.

- Lock the product scope. Start with your top healthcare system, not the entire catalog. Include the full build‑up, primers to topcoats.

- Nail the data capture. Utilities, batch cards, filler ratios, additives, packaging, inbound and outbound transport. Don’t leave modules A4–A5 for later.

- Decide the reference service life. Justify it with cleaning and maintenance realities in hospitals.

- Pre‑check digital deliverables. Ensure you will receive a human‑readable PDF and a machine‑readable dataset that LCAbyg can ingest.

Quick cues buyers notice

- EN 15804+A2 scope, verified by a recognized program operator.

- Declared unit per m² at the thickness you are selling.

- Transparent module coverage, including A4–A5 for Danish permits after July 1, 2025.

- Maintenance assumptions that match hospital SOPs, not office corridors.

Two truths to steer by

- Any valid EPD beats a missing one when LCAs are mandatory. The newest isn’t automatically favored if both are current.

- Speed matters. Teams dont wait for paperwork once climate limits and opening dates are set.

Bottom line for resinous manufacturers

If you sell into Danish healthcare, arrive with EPDs in hand for your primary systems and components. The 2025 rules make verified data a gatekeeper, not a nice‑to‑have. Do the heavy lifting once, publish cleanly, keep your datasets current, and your floors get specified for the reasons they deserve: performance, hygiene, and a climate story that stands up in the permit office.

Frequently Asked Questions

What specific CO2e limit applies to hospitals built in Denmark after July 1, 2025?

Hospitals fall under institutional building types that must document LCAs and meet a differentiated limit. Danish guidance specifies category limits by typology and introduces a separate 1.5 kg CO2e/m²/yr cap for construction process modules A4–A5. See the official BR18 pages and the Social- og Boligstyrelsen FAQ for the current tables and examples (Social- og Boligstyrelsen, 2025) (BR18, 2025).

Do I need EPDs for every layer in a resinous floor system?

Focus first on the full system you sell and its declared unit. Many winning submittals include EPDs for key components like primers and topcoats plus a system‑level declaration. Consistency to one PCR and operator helps buyers compare fairly.

Are generic database values enough for Danish LCAs?

They work in a pinch but can trigger conservative results. A product‑specific, third‑party verified EN 15804 EPD typically models closer to reality and avoids generic penalties in project LCAs (BR18, 2025).

Which manufacturers active in Denmark already publish resin floor EPDs?

Flowcrete Denmark lists EPDs in its technical library. Sika publishes EN 15804 EPDs verified by IBU for several Sikafloor products. Mapei has 2024–2025 EN 15804+A2 EPDs for Mapefloor CPU and PU systems on EPD International. Stonhard provides multiple current resinous flooring EPDs with third‑party verification. Links are available on their product or operator pages (EPD International, 2025).