Drywall EPDs, decoded

Confused by gypsum board EPDs, PCRs, plant coverage, and which numbers actually matter in bids? This guide cuts through the noise so product, sustainability, and sales teams can align fast and show up to submittals with the right PDF, not another email thread.

What “drywall” means in EPD language

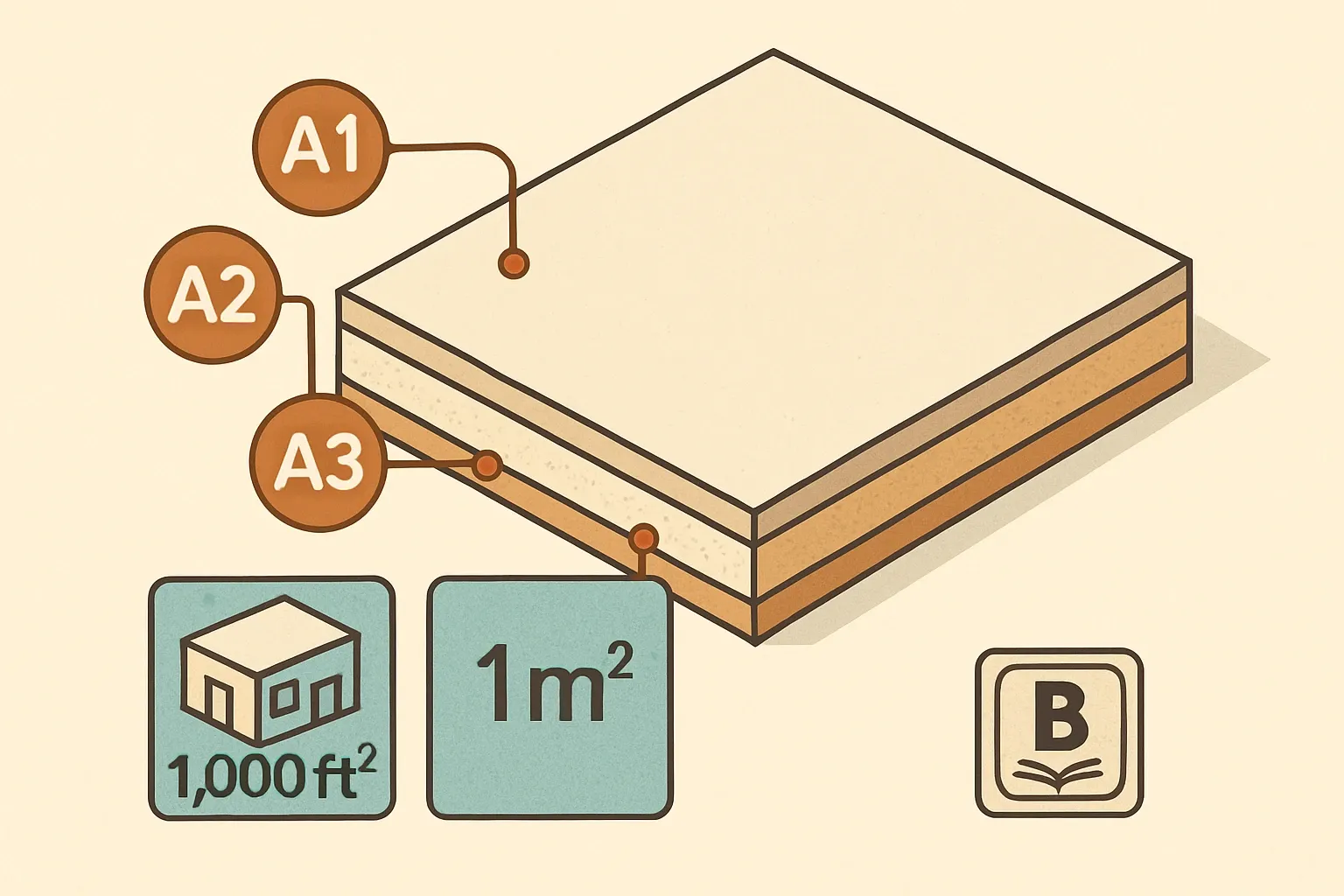

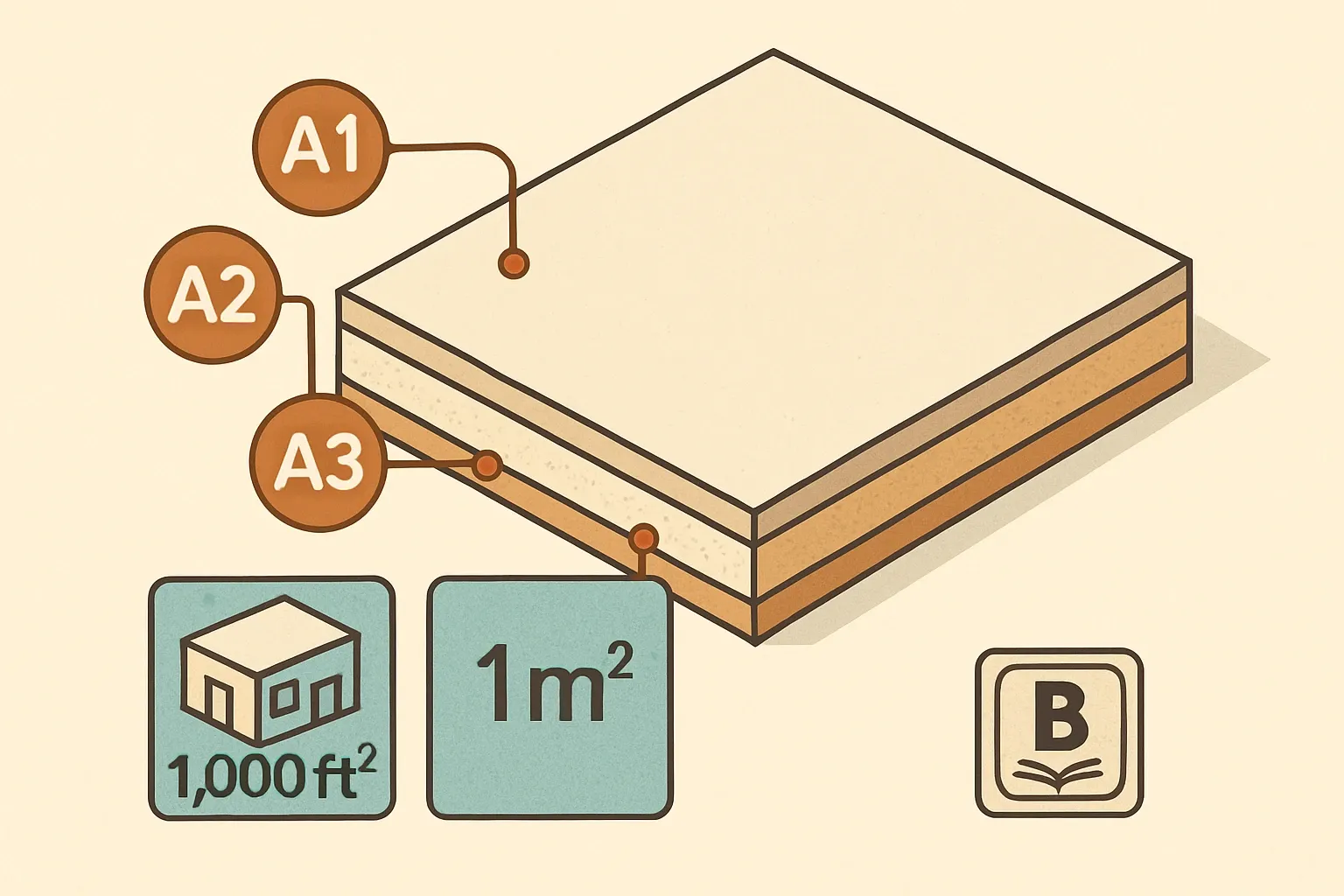

Most teams mean paper‑faced gypsum board when they say drywall. EPDs can also exist for glass‑mat gypsum panels and fiber‑reinforced boards. Cement board lives in a different category. For North America, the declared unit is usually 1,000 square feet, while many EN 15804 EPDs use 1 m². That mismatch is normal, just convert carefully when comparing.

The rulebook you must cite

A Product Category Rule is the rulebook. In 2025, the North American Part B for gypsum panels is published by Smart EPD, Standard 1000‑004 version 2. Many currently valid EPDs were created under the previous NSF PCR for Gypsum Panel Products v1.1 and will update at renewal (CLF Material Baselines, 2025). You do not need to rewrite your product to renew, you do need to follow the latest Part B when timing hits.

The carbon numbers buyers expect to see

For 1/2 in gypsum board, A1–A3 global warming potential typically spans roughly 130 to 289 kg CO2e per 1,000 ft² based on recent North American data. For 5/8 in board, the range is about 148 to 426 kg CO2e per 1,000 ft² (Carbon Leadership Forum, 2025). Those are cradle‑to‑gate manufacturing modules, not transport or install. Boards with lower basis weight per area and efficient dryers tend to land near the low end.

Two levers explain a lot of variance. First, gypsum type and sourcing. In Q1 2025, synthetic gypsum represented about 37% of total U.S. gypsum supply, which changes upstream emissions accounting in A1 depending on the local power mix and flue‑gas desulfurization flows (USGS Mineral Industry Surveys, 2025). Second, plant energy. Dryer fuel and heat recovery can swing A3 materially even for “identical” SKUs.

Plant‑specific or industry‑average

An industry‑wide EPD is acceptable in many specs, yet a plant‑specific EPD for the exact SKU usually avoids conservative adders in carbon accounting. When your project team asks for an “EPD for drywall” or a “drywall EPD,” they often mean product and plant specificity. Treat an industry‑wide document as a bridge, not a destination.

Where to find real EPDs quickly

Program operators commonly used for gypsum include Smart EPD in the U.S., NSF and UL for legacy records, and IBU or EPD International for EN 15804 publications. Many manufacturers host PDFs on product pages under Sustainability or Documents. If you distribute internationally, expect to see both ISO 21930 and EN 15804 formats. Check the declared unit before you compare.

Want the latest EPD news?

Follow us on LinkedIn to get relevant updates for your industry.

What reviewers will check on your PDF

- Declared unit matches the PCR and your comparison basis.

- PCR reference and version appear on the cover or methods section.

- Scope is clear, usually A1–A3 at minimum, with A4 and A5 reported if claimed.

- Product and plant identification are explicit, including location and date range.

- Validity dates, verifier name, and program operator ID match the registry.

- Any “lightweight” claims align with the mass per area in the technical data.

Market context that influences submittals

Six manufacturers dominate U.S. wallboard with around 60 plants. Industry shipments were about 27.9 billion square feet in calendar 2023, according to a public 10‑K that cites Gypsum Association figures (Eagle Materials 10‑K citing Gypsum Association, 2024). In the first quarter of 2025, the U.S. imported roughly 230 million square feet of wallboard and exported about 267 million square feet, with trade concentrated between Mexico and Canada. That matters because a supply substitution can force a different plant EPD in your submittal set (USGS Mineral Industry Surveys, 2025).

LEED v5, specs, and how drywall EPDs are judged

LEED v5 draft structures continue to emphasize product‑specific, third‑party verified EPDs for credit pathways. Owners care that the document is current, comparable under the correct Part B, and specific enough to avoid default penalties. Most will not split hairs over whether the EPD is one or two years old within its validity window, unless it is close to expiry.

When your team needs an EPD fast

Pick a recent reference year and lock the facility boundary early. A prospective EPD can be feasible for new lines once a few months of data exist, then you true‑up after a full year. The biggest time sink is internal data wrangling across utilities, board weights, waste, and transport. A partner who can take on white‑glove collection across plants saves your R&D and operations leaders real time. Program operator choice is largely about customer geography and comparability. Smart EPD is common in the U.S. and IBU is frequent in Europe, but you can be operator‑agnostic as long as the PCR match is correct.

Troubleshooting odd results

If your GWP jumps unexpectedly year over year, check three things before sounding alarms. Did the PCR change and shift the declared unit or data sources. Did your dryer load factor or fuel mix change. Did inbound liner or synthetic gypsum sourcing move across regions with different electricity grids. These explain most surprises. It sounds simple, but it’s definately where many audits land.

A short checklist to wrap it up

If you sell gypsum board, carry a current, product‑specific EPD for your top SKUs and a backup from an alternate plant. Keep a one‑page comparison that converts 1,000 ft² to m² for EU submittals. Track PCR expiries so renewals do not collide with a major bid. The team with the right PDF on day one tends to win the calendar, which often wins the job.

USGS Mineral Industry Surveys, 2025. Carbon Leadership Forum, 2025. Eagle Materials 10‑K citing Gypsum Association, 2024.

Frequently Asked Questions

Which PCR should apply to gypsum board EPDs in North America in 2025?

Smart EPD Part B for Gypsum Panels, Standard 1000‑004 version 2, is the current reference. Many valid EPDs are still under the 2020 NSF PCR until they renew (CLF Material Baselines, 2025).

What A1–A3 GWP values are typical for 1/2 in and 5/8 in gypsum board?

Recent North American data shows about 130 to 289 kg CO2e per 1,000 ft² for 1/2 in, and about 148 to 426 kg CO2e per 1,000 ft² for 5/8 in, depending on mass per area and plant energy efficiency (Carbon Leadership Forum, 2025).

How much of U.S. gypsum supply is synthetic right now, and why does it matter?

In Q1 2025, synthetic gypsum was roughly 37% of total U.S. supply. It changes upstream A1 accounting and can shift total GWP based on regional power mixes and FGD byproduct flows (USGS Mineral Industry Surveys, 2025).