Concrete EPDs, Explained For Busy Manufacturers

If customers ask for an EPD for concrete, they are not playing a paperwork game. They are trying to compare global warming potential, reliably, across mixes and suppliers. This guide shows how a concrete EPD is built, which choices actually shift the number, and how to get one published quickly without burying your technical team in spreadsheets.

What a concrete EPD actually covers

A concrete EPD reports cradle to gate impacts for a declared unit, usually one cubic meter of a specific mix, under EN 15804 and ISO 14025 rules. Think of the PCR as the rulebook of Monopoly, ignore it and the game falls apart. Most buyers care first about GWP, then durability and density details that feed into project models.

Cement dominates the footprint because of clinker production, which is energy and process intensive. The cement sector is responsible for roughly 7 percent of global energy system CO₂ emissions, a stark reminder of why mix design choices matter (IEA, 2024).

Which EPD do specifiers actually want

Industry‑wide EPDs are helpful as context. Plant‑specific EPDs improve credibility. Mix‑specific, product‑specific EPDs are what win head‑to‑head comparisons, because they match the submittal exactly. If the project needs a 5,000 psi mix with a certain slump and SCM blend, a generic average cannot stand in for that.

Digital, machine‑readable EPDs make procurement portals and design software happier. They shrink submittal back‑and‑forth and keep the spec from drifting late in the bid cycle.

The data your plant needs to have ready

Concrete EPDs are built on one reference year of data. Pull it consistently across sites if you operate more than one plant. A pragmatic checklist helps:

- Incoming materials, suppliers, and monthly volumes for cement, SCMs, aggregates, admixtures

- Fuel and electricity use by the plant, plus water intake, reclaimer, and wastewater

- Returned concrete, waste handling, and any on‑site recycling

- Transport distances and modes for major inputs, especially cement and SCMs

- The exact mix recipe, batching tolerances, and production volume for the declared mix

Pick a partner who handles the heavy lift on data wrangling and project management so operations and QC stay focused on production.

Want to boost your concrete EPD strategy?

Follow us on LinkedIn for insights that help you unlock new business opportunities in project specifications.

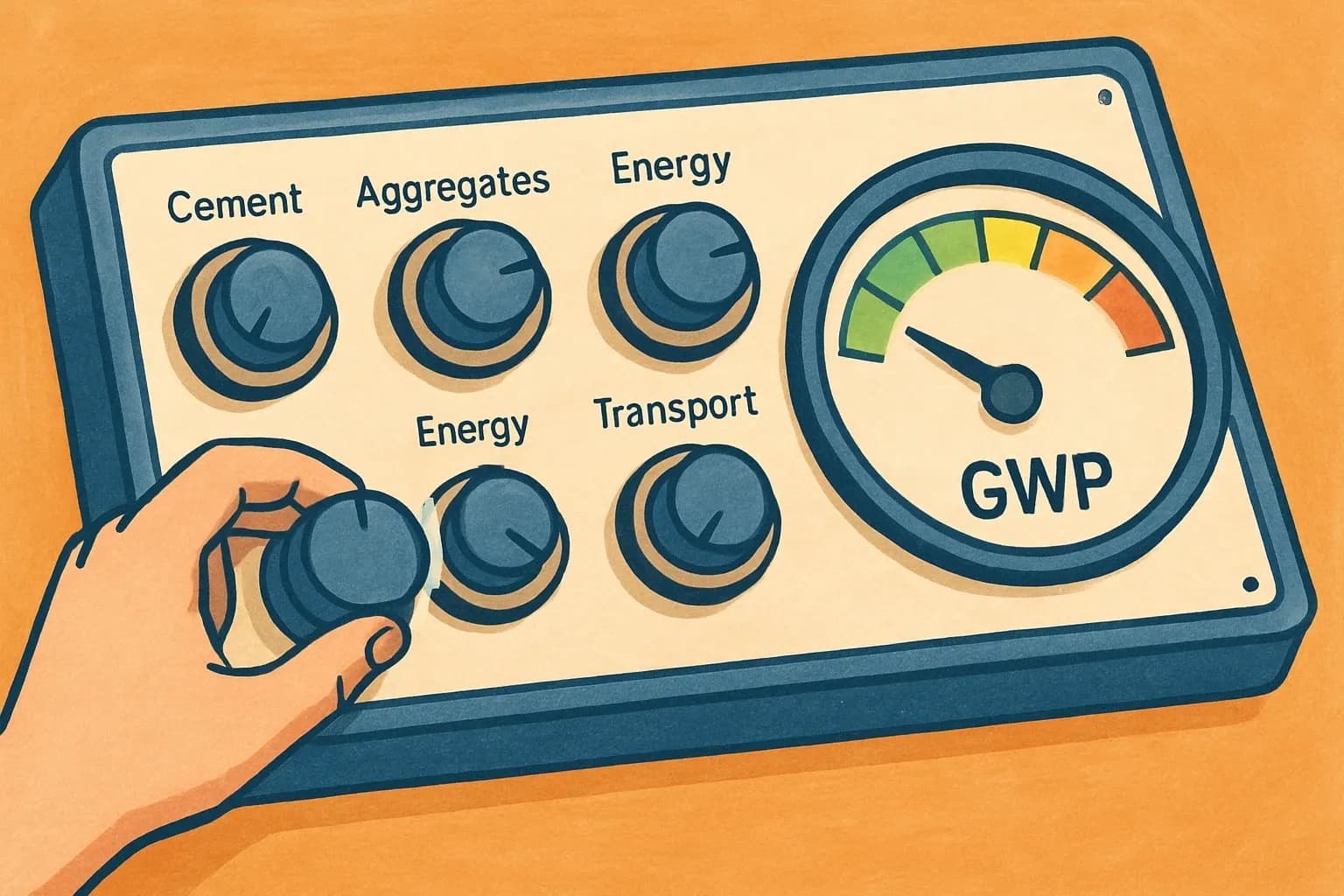

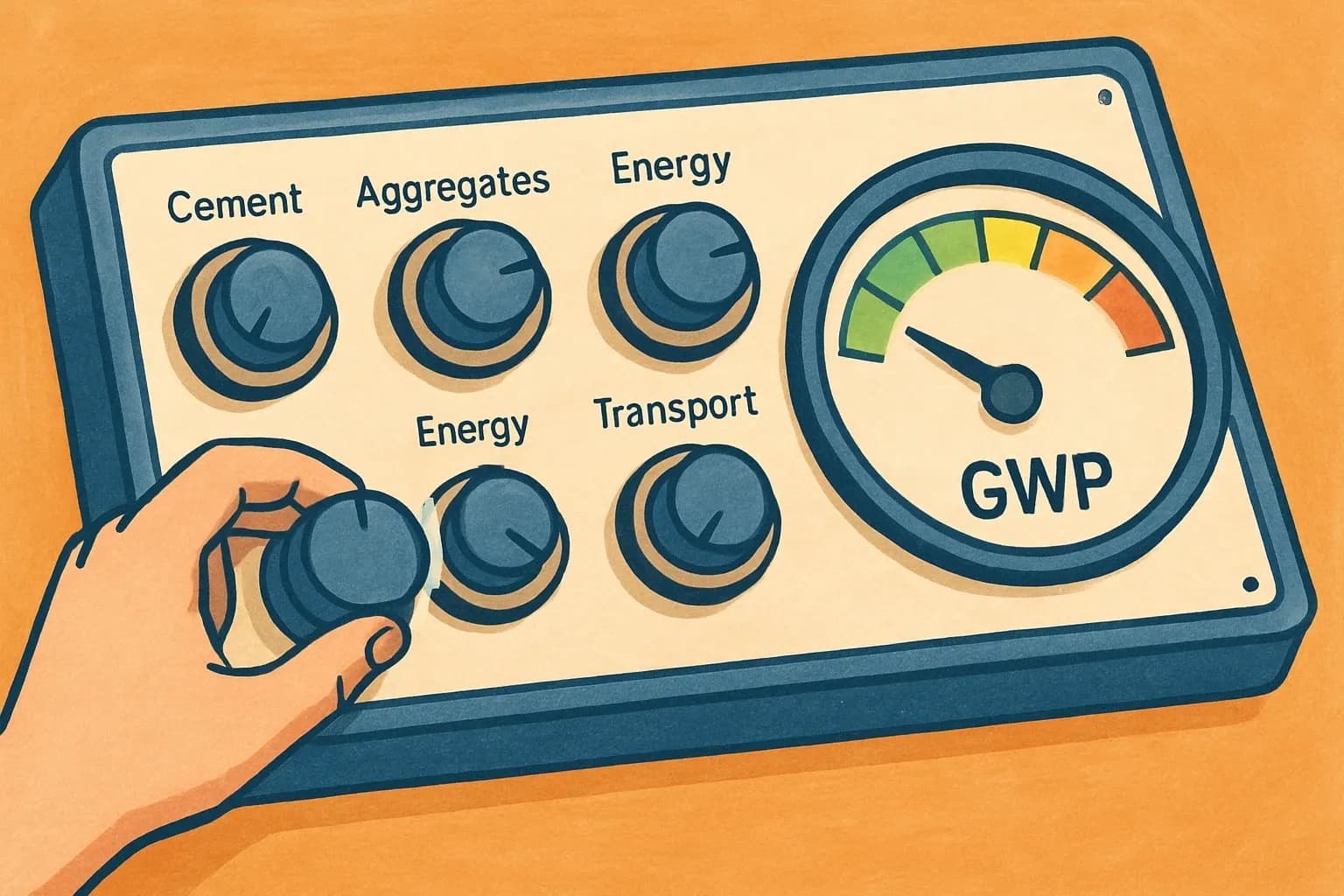

Mix design levers that move the number

Supplementary cementitious materials reduce clinker intensity while keeping performance. Fly ash, slag cement, natural pozzolans, and calcined clay can all help, within local availability and specification limits. Optimized aggregate gradation and water reducers trim paste volume, which indirectly trims cement.

Pay attention to curing and strength development. If early strength is non‑negotiable, consider strength‑activity indexes for SCMs and admixture strategies that keep cement content from creeping up.

Program operators and the rules of the road

In the United States, common program operators for concrete include Smart EPD, UL, ASTM International, and NSF. In Europe, IBU and EPD International are frequent publishers. What matters is that the EPD is third‑party verified under an applicable PCR, and that the operator supports digital distribution so your EPD shows up where specifiers are searching.

PCRs do expire on a schedule, yet your published EPD typically remains valid through its stated validity window. On renewal, the updated PCR version will apply.

Regional realities, grid power, and trucking

Two identical mixes made on two grids can carry different footprints because electricity matters in cement grinding, SCM processing, and plant operations. Regional grid CO₂ emission rates in the United States vary by more than twofold, which changes the background LCA math for otherwise similar plants (EPA eGRID, 2024).

SCM sourcing can also swing results. If slag must travel long distances, the transport segment can nibble away at the benefit. Keep actual supplier routes in your data pack and do not guess.

Timelines, validity, and refresh cycles

Most concrete EPDs are completed in a few weeks once clean data lands. Validity periods are multi‑year, set by the program operator, and renewals are smoother when your data collection is systematized rather than heroic.

For brand‑new mixes already in production, a prospective EPD based on several months of data can be acceptable, then trued up after a full year. Teams that document along the way avoid the quarter‑end scramble.

Quality moves that auditors notice

Tie every input to invoices or system exports. Lock supplier IDs to materials to avoid name drift. Document batching tolerances and QC rejects. If you adjust admixture dosages seasonally, note the ranges. Small habits here save big cycles with verifiers later.

ASTM C94 sets time and temperature expectations for ready‑mixed delivery, which your EPD should reflect in transport and plant assumptions rather than generic placeholders (ASTM C94, 2023).

Where concrete EPDs show commercial ROI

Owners and design teams increasingly gate submittals on product‑specific EPDs, especially as LEED v5 moves transparency up the scoring ladder. Without one, project carbon accounting often defaults to conservative values that make your mix look worse than it performs. An EPD lowers friction, keeps your mix in the conversation, and reduces the odds of a late swap.

Sales teams also benefit from a single source of truth. A machine‑readable EPD plugged into quoting tools means a faster, cleaner handoff from preconstruction to plant.

Put it together without the chaos

The fastest path is simple. Decide which mixes matter for revenue this quarter. Gather one clean reference year of data. Choose a program operator aligned with your markets. Select an LCA partner that takes on the spreadsheet hunting so your best people do not. Publish, then refresh on a predictable cadence. It is not magic, but it is definately manageable when the process is built for concrete.

Frequently Asked Questions

Is an industry‑wide EPD enough for concrete bids that ask for an EPD?

Usually not. Industry‑wide EPDs provide context, but most bids prefer product‑specific EPDs tied to the exact mix because they enable fair GWP comparisons for that submittal.

What declared unit should we use for a concrete EPD?

Most PCRs for concrete specify one cubic meter as the declared unit under EN 15804. Some North American specifications still talk in cubic yards, so include a clear conversion in documentation.

Do we need a separate EPD for every strength class and slump?

Not always. Publish for the mixes that drive revenue or are most frequently specified, then expand. Grouping by strength class with representative SCM blends is common when mixes share the same plant and materials.

How often should we refresh a concrete EPD?

Plan on a multi‑year validity window with a refresh at renewal or sooner if major changes occur in cement type, SCM rates, or suppliers that materially shift GWP.

Which single lever typically cuts GWP the most in concrete?

Reducing clinker intensity via SCMs, while maintaining performance, is the most consistent lever. Regional electricity and transport then fine‑tune results.