EPD Automation, Explained For Manufacturers

If EPDs feel like a maze of spreadsheets, supplier emails, and last‑minute scrambles, you are not alone. Automation can turn that maze into a mapped route. The trick is knowing what to automate, what to keep human, and how to avoid traps that quietly add months. Let’s make the moving parts visible so you can move faster without risking credibility or compliance.

What automation can and cannot do

Automation moves data, enforces rules, and watches for change. It does not set system boundaries or choose the right PCR. Think of it like cruise control on a steep mountain road. Helpful, fast, and safe when used well. Still not the driver.

Automate the pulls and checks. Keep the judgment calls human. Automation don't replace good judgment.

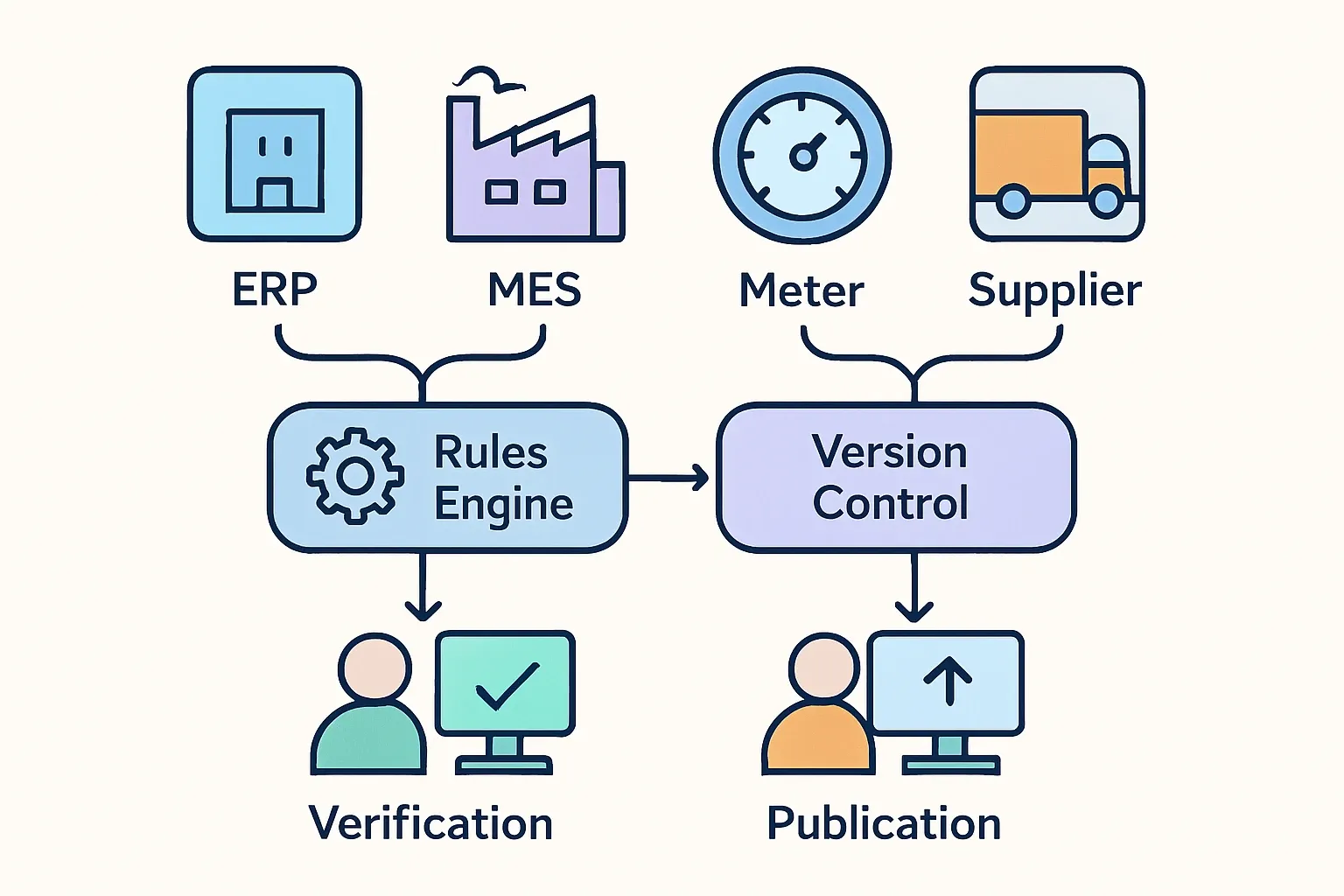

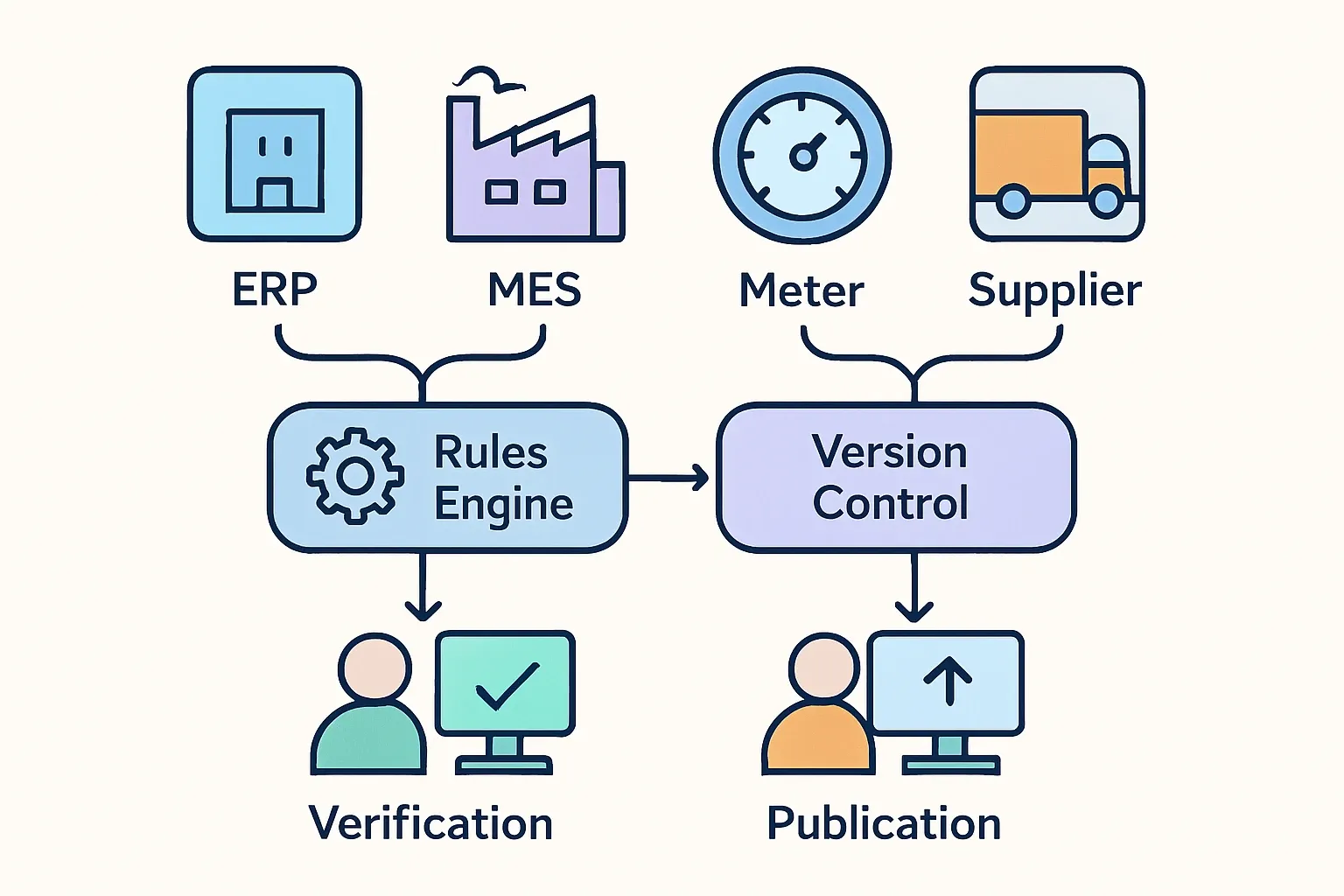

The data stack behind an automated EPD

At minimum you need clean links to your ERP or PLM for bill of materials, MES for throughput, utility meters for energy, and purchasing for suppliers. Add a mapping layer that converts internal codes into LCI datasets and transport models. Finish with a publication workflow that packages results to a program operator template and hands off for third‑party review.

Two things define mature stacks. Version control on every input and a rules engine that blocks runs when required fields or PCR conditions are missing.

PCRs still rule the game

A PCR is the rulebook of Monopoly. Ignore it and the game falls apart. Good automation reads the rulebook before rolling the dice. It locks in declared unit, system boundaries, cut‑offs, and allocation choices, then warns when a PCR revision lands.

Most program operators set EPD validity to five years (The International EPD System, 2024). EN 15804+A2 lists 13 impact indicators that must be reported for construction products (EN 15804+A2, 2019). Your automation should validate that every run populates those indicators correctly.

From one‑off projects to continuous updates

Treat EPDs less like a book you publish once and more like a playlist you refresh. Trigger reruns when energy mix shifts, suppliers change, a plant opens, or a formulation is tuned. Many teams anchor data to a 12‑month reference year and run quarterly deltas to catch swings early.

Verification and operator workflows

Third‑party verification remains mandatory for credible declarations. Automation helps by packaging evidence, creating clear audit trails, and aligning outputs to operator templates. In the US, Smart EPD is common. In Europe, IBU is frequent. Strong pipelines reduce back‑and‑forth during verification and cut calendar time without cutting corners.

Want the latest EPD news?

Follow us on LinkedIn to get relevant updates for your industry.

Electricity factors at scale

Power data can make or break your GWP. Use metered kWh, then apply regionally accurate emission factors. The US eGRID divides the country into 26 subregions used for electricity emission factors (EPA eGRID, 2024). Good systems bind each facility to the correct subregion and document market‑based versus location‑based choices.

What to automate vs what to keep human

Automate

- Data collection from ERP, MES, meters, and purchasing

- Unit conversions, transport defaults, and dataset mapping

- Change detection, rerun triggers, and audit trails

Keep human

- Goal and scope decisions, including allocation and cut‑offs

- PCR selection when multiple are plausible

- Final review of claims language and visuals in the EPD

Common pitfalls that slow teams down

- Ambiguous product variants that hide behind one SKU and explode your declared unit

- Supplier data that arrives as PDFs without machine‑readable fields

- Plant‑level energy that mixes processes, making allocation messy

- PCR expiry not tracked, so an otherwise solid draft slips on timing

Evaluating an “EPD automation” offer

- Proof of integrations with your actual systems, not just generic APIs

- A data model that supports multi‑plant, multi‑market products without copy‑paste

- EN 15804+A2 validation baked into the pipeline, not a checklist after the fact

- Clear verification handoff and experience with your preferred operator

- Role‑based permissions and immutable audit logs for every change

- A white‑glove plan for supplier engagement and data wrangling, since that is where hours really go

The policy context that still matters

Many federal incentives shifted in early 2025, so count less on headline grants and more on owner specs, state Buy Clean rules, and LEED v5 momentum. Product‑specific EPDs remain a powerful way to stay in the room when carbon targets apply. That is where automation quietly pays back, by keeping credentials current without another all‑hands fire drill.

A faster path without cutting corners

The best setups are boring in the best way. Clean connectors in, rigorous checks in the middle, reliable packages out. People decide the tricky parts. Software keeps the promises. Do that well and your team definitley trades spreadsheet marathons for faster specs and fewer surprises.

Frequently Asked Questions

How long is an EPD typically valid and how should automation plan around expiry?

Most operators set five years as the validity window. Build expiry alerts and PCR‑revision checks so reruns and re‑verification are scheduled well before the validity date (The International EPD System, 2024).

Which impact indicators must an automated run include under EN 15804+A2?

Thirteen indicators are required for construction products, including global warming potential, acidification, eutrophication, and resource use. Your pipeline should validate presence and units for each before packaging (EN 15804+A2, 2019).

How should electricity emission factors be handled across multiple US plants?

Bind each site to its eGRID subregion, use metered kWh, choose market‑based or location‑based consistently, and document it. The US uses 26 eGRID subregions for emission factor allocation (EPA eGRID, 2024).